High Quality Car Bumper Molding Manufacturer Supplier Company

Car bumpers serve an essential role in protecting the vehicle during minor collisions, helping to damage to the body and essential parts. Over time, as the automotive industry has evolved, so too has the need for enhanced protection, aesthetics, and durability in bumper designs. One often overlooked yet highly significant component of modern bumpers is Car Bumper Molding. This component not only contributes to the visual appeal of the vehicle but also plays an important role in its overall functionality.

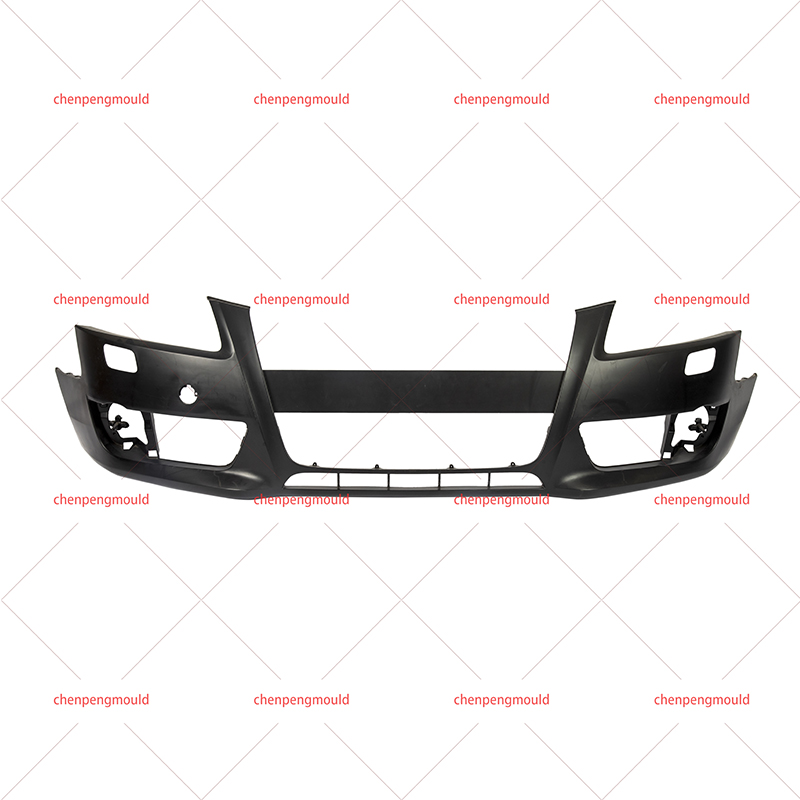

Car Bumper Molding refers to the trim or decorative elements installed along the edges or surface of the bumper. These moldings are designed to enhance the bumper's appearance, providing a more polished, finished look while offering protection against minor impacts. They are typically made from a variety of materials, including plastic, rubber, or metal, and can be found on both the front and rear bumpers of modern vehicles.

The primary purpose of Car Bumper Molding is to absorb shock during low-impact collisions. In addition to this protective role, it also serves an aesthetic function by adding sleek, dynamic lines to the vehicle’s exterior. While Car Bumper Molding is commonly associated with luxury and sportier vehicles, it is now available for all types of vehicles, making it an accessible option for a wide range of car owners.

One of the standout characteristics of Car Bumper Molding is its durability. Given the location of bumpers on a vehicle, they are subjected to harsh environmental conditions, including UV rays, rain, snow, and road salt. As such, Car Bumper Molding must be made from materials that can withstand exposure to these elements without degrading.

Many bumpers are now equipped with moldings crafted from high-quality plastic or thermoplastic elastomers (TPE), which offer resistance to UV rays and temperature fluctuations. These materials do not fade, crack, or discolor easily, ensuring that the Car Bumper Molding retains its original appearance over time. Additionally, some moldings feature coatings that provide further protection against scratches and scuffs, keeping the bumper looking new and well-maintained even in adverse conditions.

Car Bumper Molding is available in a wide range of materials, each offering different characteristics suited to specific needs. Some of the common materials used include:

Plastic: High-density polyethylene (HDPE) and polypropylene are commonly used for Car Bumper Molding because of their strength, flexibility, and lightweight properties. These plastics are resistant to impacts and can absorb energy without cracking or breaking. They are also cost-effective, making them popular in mass-market vehicles.

Rubber: Rubber moldings are often used for added protection, especially in the form of impact strips. The flexibility of rubber allows the Car Bumper Molding to cushion against minor collisions, preventing dents and scratches. Additionally, rubber bumpers provide a non-abrasive surface, reducing the risk of paint chipping when in contact with other surfaces.

Stainless Steel or Aluminum: For higher-end vehicles or those requiring additional strength, Car Bumper Molding may be crafted from stainless steel or aluminum. These metals are corrosion-resistant and can withstand harsher impacts while also adding a premium, polished appearance to the vehicle. These metal moldings are often found in luxury cars, sports cars, and heavy-duty trucks.

Each material choice for Car Bumper Molding offers a unique combination of durability, aesthetic appeal, and protection, allowing vehicle manufacturers and owners to select the right molding based on their preferences and requiremen

+86-18357617666

+86-18357617666