China Car Middle Grille Bumper Molding Mould Manufacturer Factory

In automotive manufacturing, the processes and components involved in creating middle grille molds and car bumper moldings are distinct yet integral to the overall design and functionality of vehicles.

Middle Grille Mould: Definition and Functionality

The middle grille mold, also known as the radiator grille mold, is a component located at the front of a vehicle, typically between the headlights. Its primary function is aesthetic and practical, serving as an air intake grille that allows airflow to the radiator and engine compartment. Beyond its functional role in cooling the engine, the middle grille mold contributes significantly to the vehicle's exterior design, reflecting brand identity and stylistic preferences.

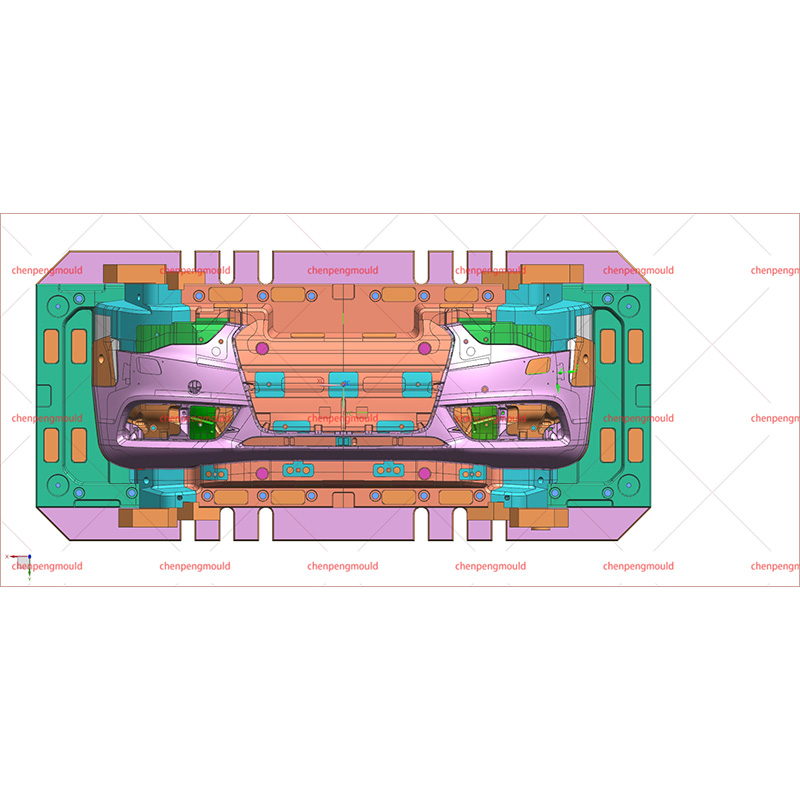

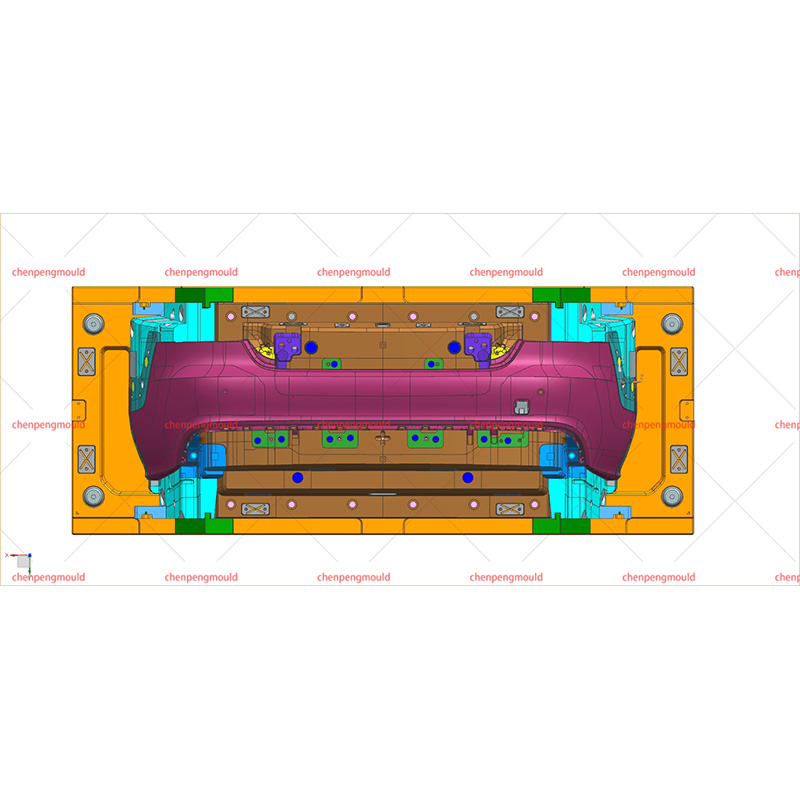

Middle grille molds are manufactured using injection molding processes, which involve injecting molten plastic material into a mold cavity under high pressure. This method allows for precise detailing and customization of grille designs, including patterns, textures, and integrated emblem placements. Materials commonly used for middle grille molds include ABS (Acrylonitrile Butadiene Styrene) and polypropylene, chosen for their durability, impact resistance, and ability to withstand varying environmental conditions.

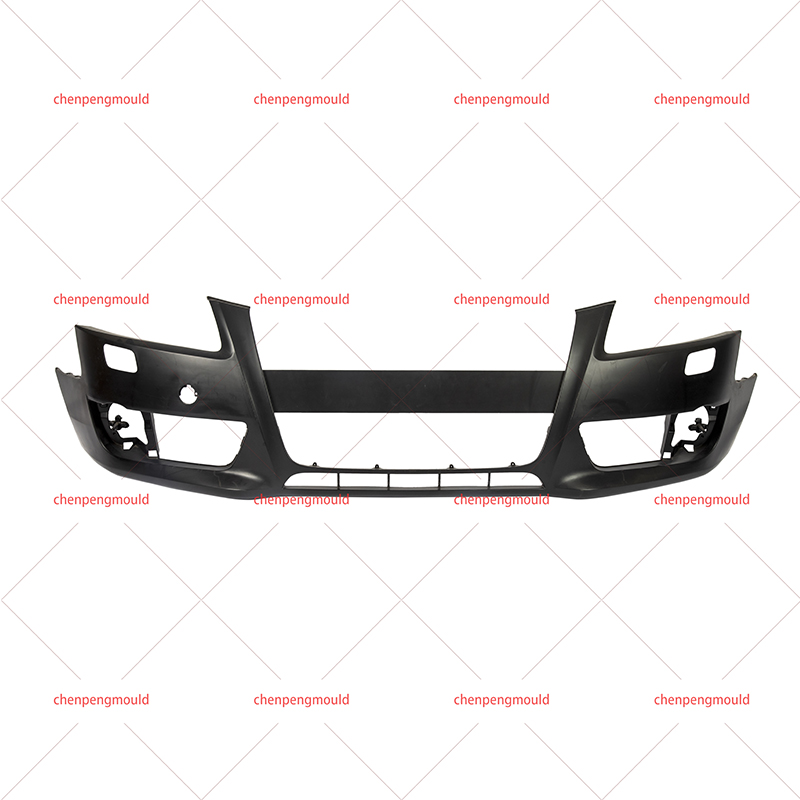

Car Bumper Molding: Overview and Purpose

Car bumper molding refers to the process of manufacturing bumpers, which are critical safety components designed to absorb impact during collisions, protecting vehicle occupants and reducing damage to underlying mechanical components. Unlike middle grille molds, which primarily serve aesthetic and airflow management purposes, car bumper molding focuses on enhancing vehicle safety and structural integrity.

The production of car bumper moldings involves advanced engineering and material sciences to meet stringent safety standards and regulatory requirements worldwide. Manufacturers utilize various molding techniques, including injection molding, compression molding, and thermoforming, depending on the bumper's design complexity and material specifications.

Differences in Design and Manufacturing Techniques

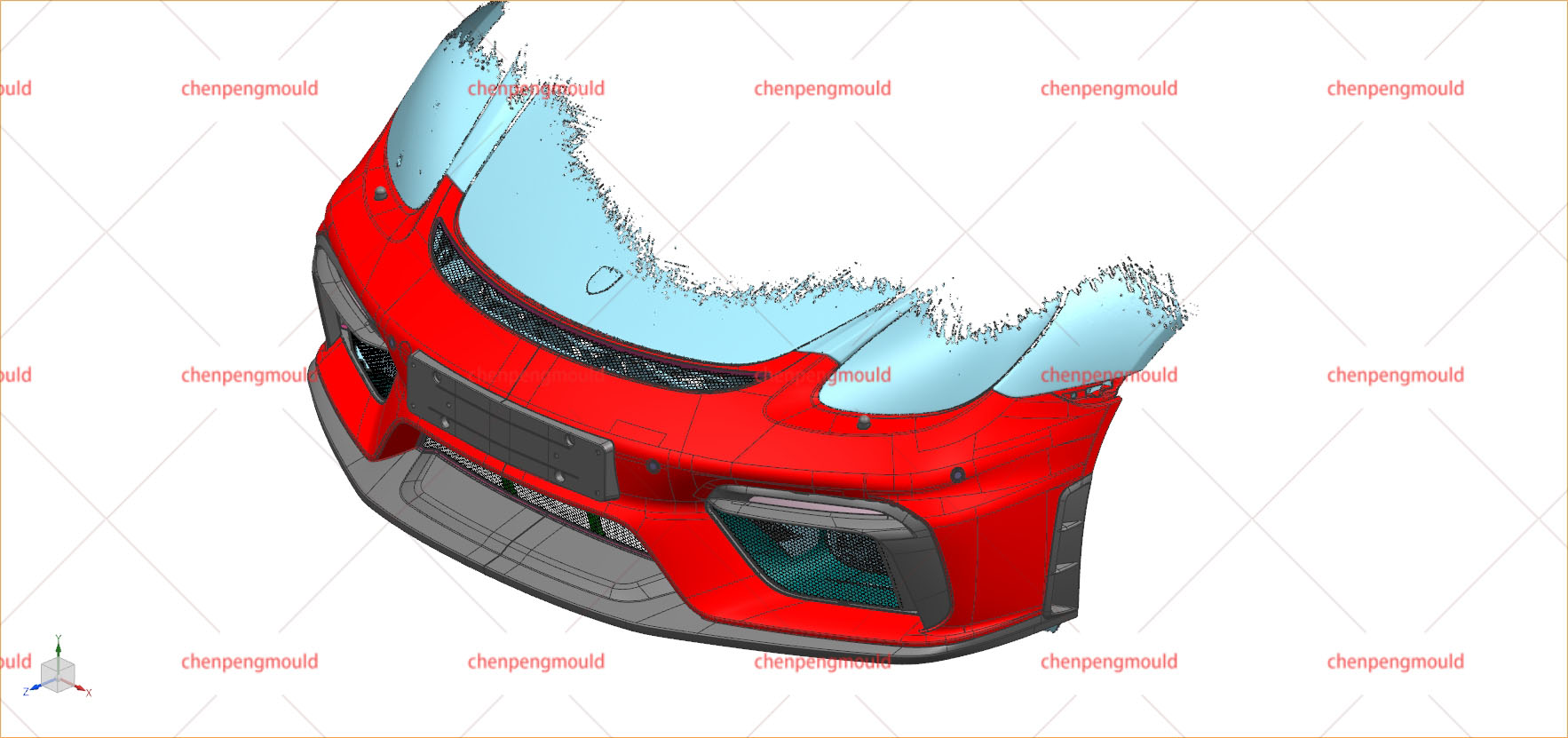

Design Complexity: Middle grille molds often feature intricate designs with detailed patterns and textures to complement the vehicle's front-end aesthetics. In contrast, car bumper moldings prioritize impact absorption and structural resilience, requiring robust designs capable of withstanding high-energy impacts.

Material Selection: While both middle grille molds and car bumper moldings are typically made from thermoplastic materials, the specific material choices differ. Car bumpers often utilize reinforced plastics, such as polypropylene with glass fiber reinforcement, to enhance strength and impact resistance. Middle grille molds may use ABS or other plastics suited for exterior applications where aesthetics are paramount.

Functionality and Integration: Middle grille molds integrate with other vehicle components, such as headlights and emblem badges, to enhance the vehicle's frontal appearance. Car bumper moldings, on the other hand, are designed for functional integration with crash sensors, fog lights, and energy absorption structures to ensure effective vehicle safety performance.

Applications and Industry Standards

Middle grille molds and car bumper moldings adhere to distinct industry standards and regulatory frameworks governing vehicle safety, design aesthetics, and environmental impact. Manufacturers must comply with safety standards, such as those set by the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe, to ensure vehicle compliance and consumer safety.

In terms of application, middle grille molds contribute to the visual identity and brand differentiation of vehicles across various automotive segments, including sedans, SUVs, and luxury vehicles. Car bumper moldings are essential components in both passenger vehicles and commercial fleets, providing critical protection against collisions and enhancing overall vehicle durability.

Technological Advancements and Future Trends

Advancements in automotive manufacturing technologies continue to influence the design and production of middle grille molds and car bumper moldings. Innovations in mold design software, robotics, and additive manufacturing (3D printing) enable faster prototyping, customization, and production scalability.

+86-18357617666

+86-18357617666