Custom Modified Bumper Injection Molding Mould Sale Supplier

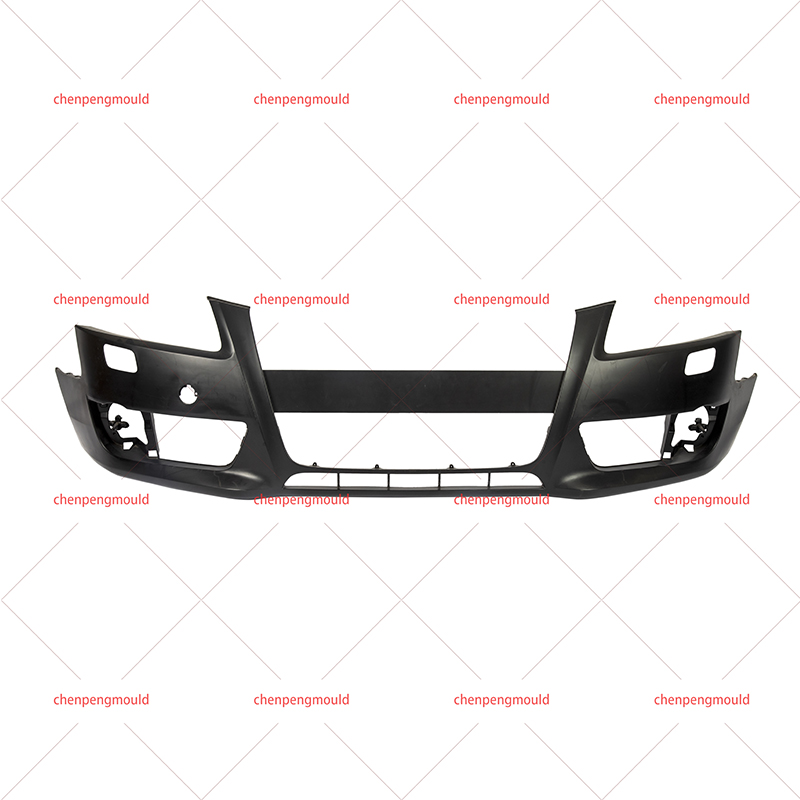

In the automotive industry, the functionality and aesthetics of vehicle bumpers are crucial for both safety and design. Modified bumper molding represents an advanced approach to producing bumpers that not only meet standard requirements but also address specific design needs and performance enhancements.

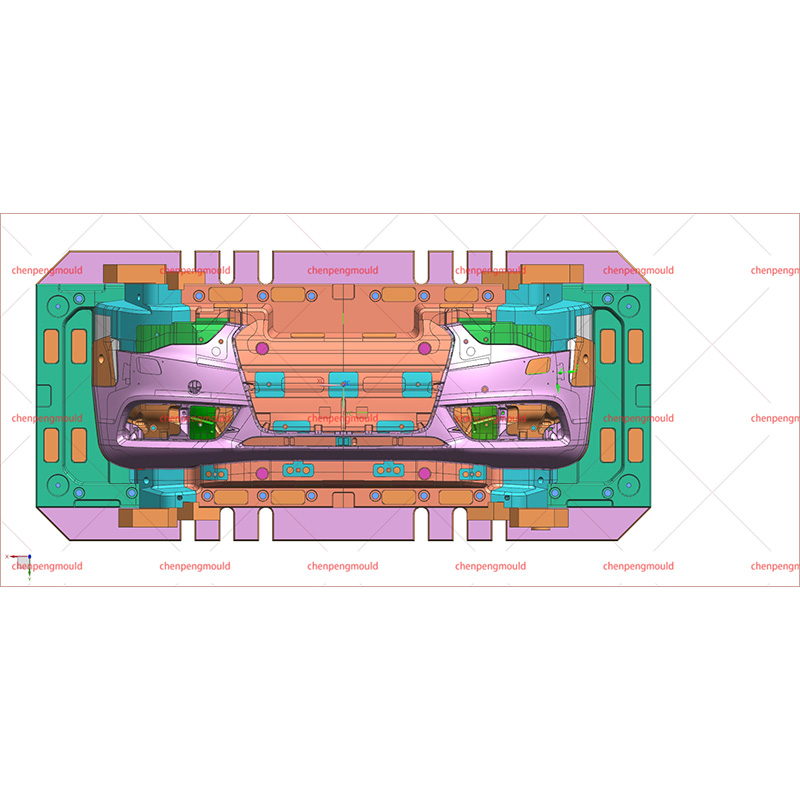

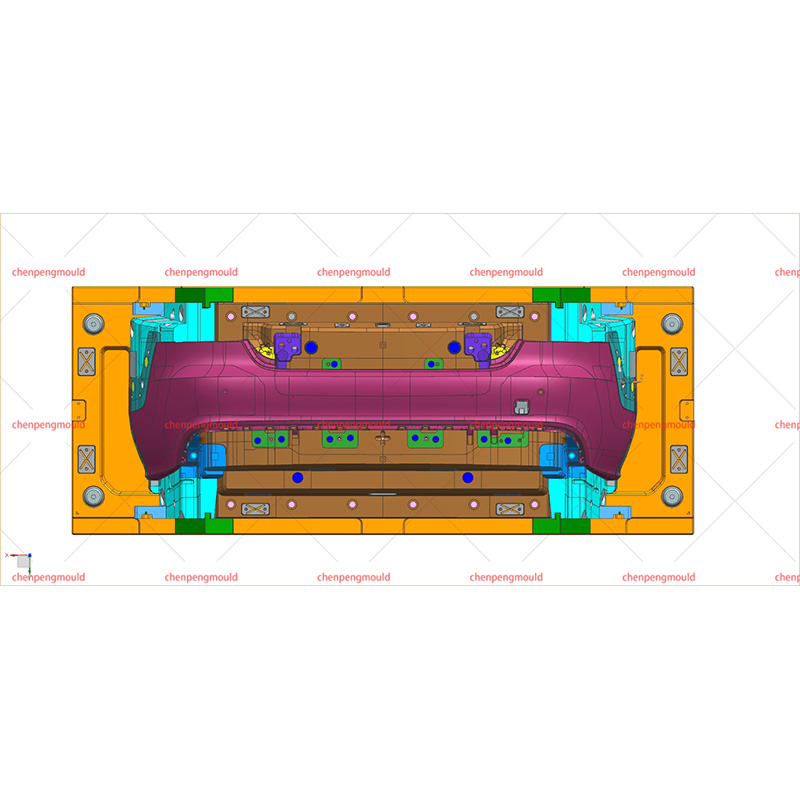

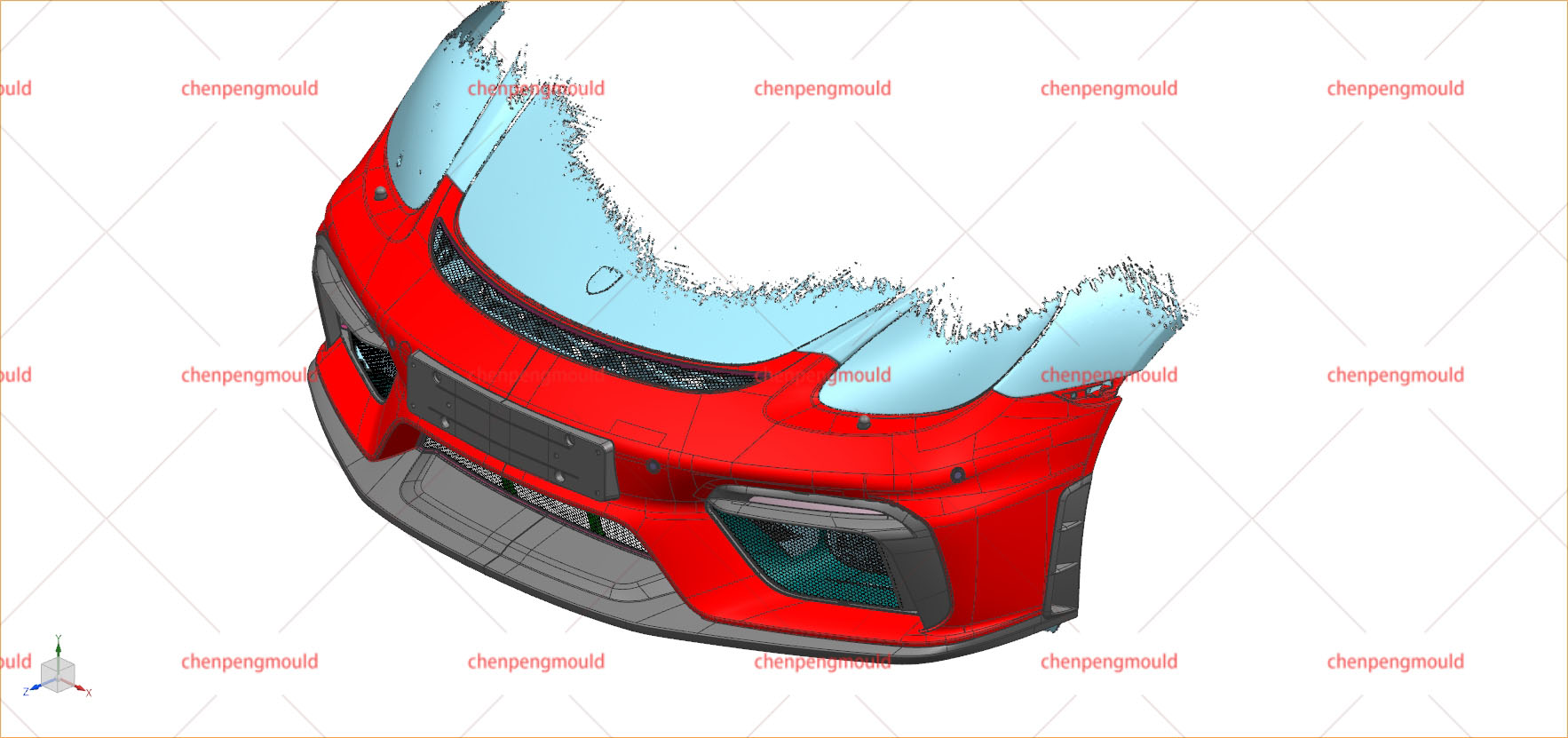

One of the defining characteristics of modified bumper molding is its enhanced design flexibility. Unlike traditional bumper molding methods, which may be limited in their design scope, modified molding techniques allow for a greater range of shapes, sizes, and details. This flexibility is achieved through advanced molding technologies and materials that enable the creation of bumpers with intricate designs and integrated features.

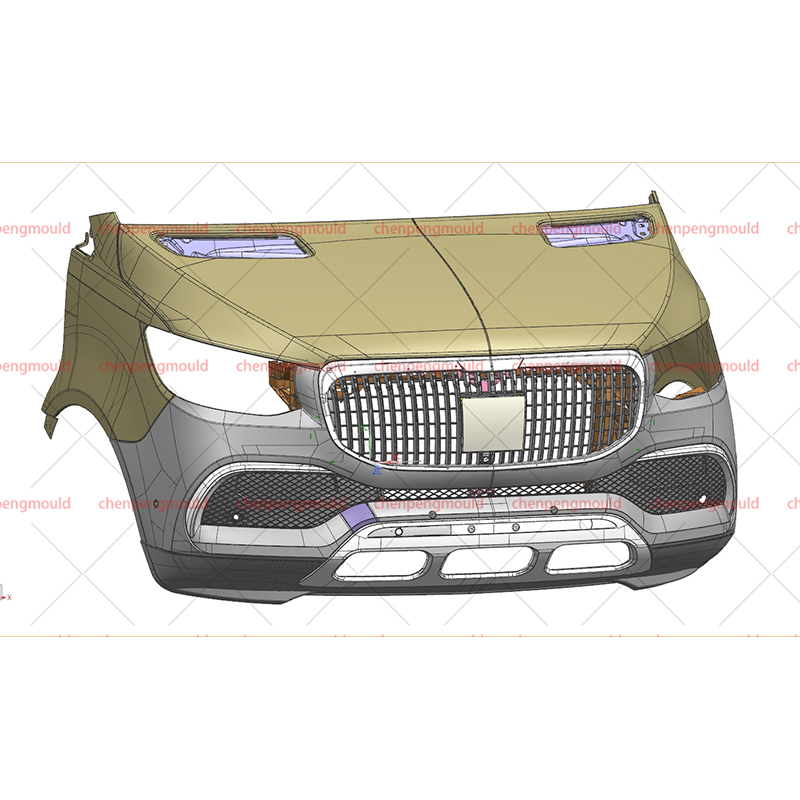

Complex Geometries: Modified molding techniques can produce bumpers with complex geometries and contours that are tailored to specific vehicle models. This capability allows manufacturers to incorporate aerodynamic elements, distinctive styling cues, or functional components directly into the bumper design.

Custom Integrations: Modern bumpers often include integrated features such as sensors, grille openings, or lighting elements. Modified molding processes can accommodate these integrations seamlessly, resulting in bumpers that offer both aesthetic appeal and enhanced functionality.

Modified bumper molding often involves the use of advanced materials that provide performance characteristics compared to traditional options. These materials are selected for their specific properties, such as impact resistance, weight reduction, and durability.

Reinforced Plastics: Modified bumpers frequently use reinforced plastics, such as polypropylene composites or thermoplastic elastomers, which offer improved strength and impact resistance. These materials are designed to withstand everyday wear and tear while maintaining their appearance and functionality over time.

Innovative Composites: In some cases, modified bumper molding employs advanced composite materials that combine the benefits of different substances. For example, composite materials may blend fibers with plastics to enhance strength without significantly increasing weight.

The impact resistance of bumpers is a critical consideration, and modified bumper molding addresses this aspect with notable improvements. Modern bumpers are designed to absorb and dissipate impact energy, reducing the likelihood of damage to the vehicle's structural components and enhancing occupant safety.

Energy-Absorbing Structures: Modified bumpers often feature energy-absorbing structures or foam inserts that help distribute impact forces more evenly. These features contribute to better protection during collisions and reduce the risk of injury to occupants.

Durability Enhancements: Advanced materials and manufacturing techniques used in modified bumper molding enhance the durability of the bumpers. These enhancements help prevent deformation, cracking, or other forms of damage that can occur due to impacts or environmental factors.

Aesthetic customization is another significant characteristic of modified bumper molding. The ability to tailor the appearance of bumpers to match specific design preferences is a valuable feature for manufacturers and consumers alike.

Varied Finishes: Modified molding techniques allow for a wide range of finishes, including matte, gloss, or textured surfaces. This versatility enables manufacturers to offer bumpers that complement the overall design of the vehicle and meet individual customer preferences.

Color Integration: Modern bumper molding processes can incorporate color directly into the material, reducing the need for painting and improving color consistency. This approach can streamline production and offer greater design flexibility in terms of color choices.

+86-18357617666

+86-18357617666