In the realm of automotive manufacturing, the production of Stainless Steel Bumper and Lower Grill Molding is a meticulous and intricate process that demands precision and attention to detail.

Stage 1: Material Selection

The foundation of any quality Stainless Steel Bumper and Lower Grill Molding begins with the careful selection of materials. Stainless steel is chosen for its exceptional qualities, including corrosion resistance, durability, and a sleek finish. The manufacturing process prioritizes sourcing high-quality stainless steel that meets industry standards, ensuring that the final product will not only withstand the rigors of the road but also exude a timeless and polished appearance.

Stage 2: Precision Cutting

Once the stainless steel sheets are procured, the manufacturing process kicks off with precision cutting. Advanced machinery is employed to ensure accurate dimensions for the bumper and lower grill molding. The use of computer-controlled cutting tools guarantees that each piece is cut to exact specifications, laying the groundwork for a seamless assembly process.

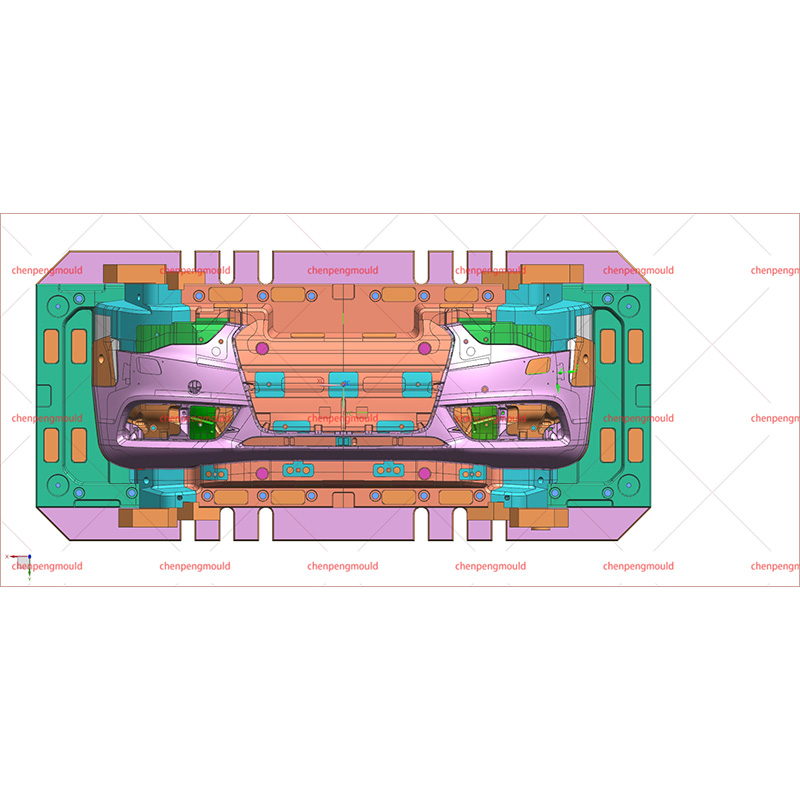

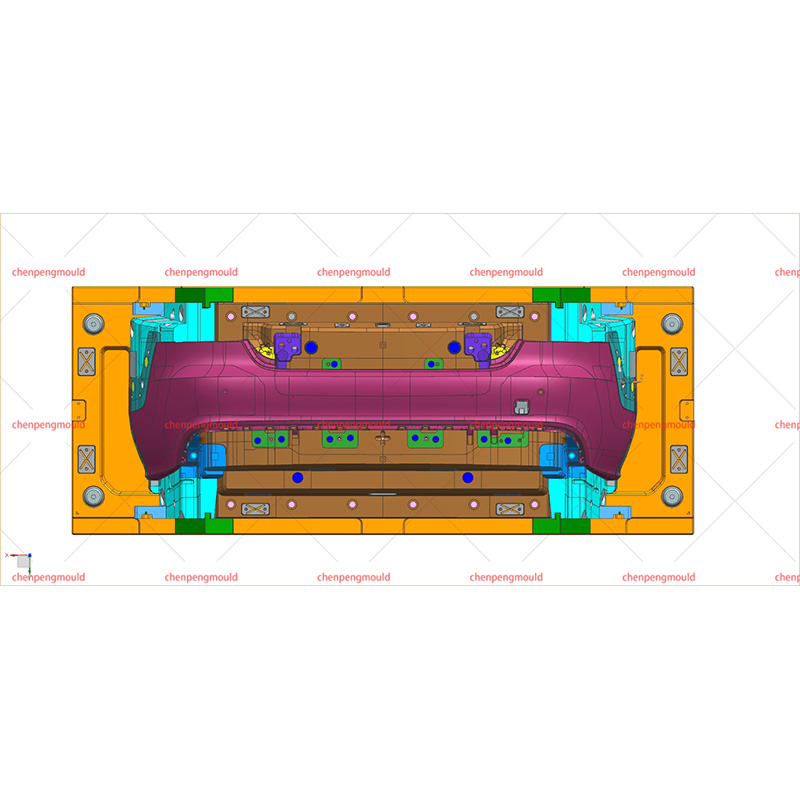

Stage 3: Forming and Shaping

The cut stainless steel pieces then undergo a series of forming and shaping processes. Hydraulic presses and molds are utilized to bend and shape the metal into the distinctive contours required for the bumper and lower grill molding. This stage demands a high level of craftsmanship, as the precision in forming determines the final fit and appearance of the components on the vehicle.

Stage 4: Welding and Bonding

Welding plays a pivotal role in the assembly of Stainless Steel Bumper and Lower Grill Molding. Skilled welders employ various techniques, including TIG and MIG welding, to join the different components seamlessly. The welding process not only ensures structural integrity but also contributes to the overall robustness of the bumper and grill molding. In addition to welding, bonding techniques may be employed to reinforce specific joints, adding an extra layer of strength to the final product.

Stage 5: Surface Treatment

The surface treatment of stainless steel is a critical step to achieve the desired aesthetic and functional qualities. The components undergo polishing to enhance the shine and reflective properties of the stainless steel. Additionally, surface treatments such as chrome plating or powder coating may be applied to further enhance corrosion resistance and provide a customizable finish. This stage is where the sleek and lustrous appearance of Stainless Steel Bumper Molding truly comes to life, elevating the visual appeal of the vehicle.

Stage 6: Quality Control

Stringent quality control measures are implemented throughout the manufacturing process. Each stainless steel bumper and lower grill molding undergoes thorough inspection to ensure it meets strict quality standards. This includes dimensional checks, surface finish assessments, and structural integrity evaluations. Any deviation from the specified criteria prompts immediate corrective actions to maintain the excellence of the final product.

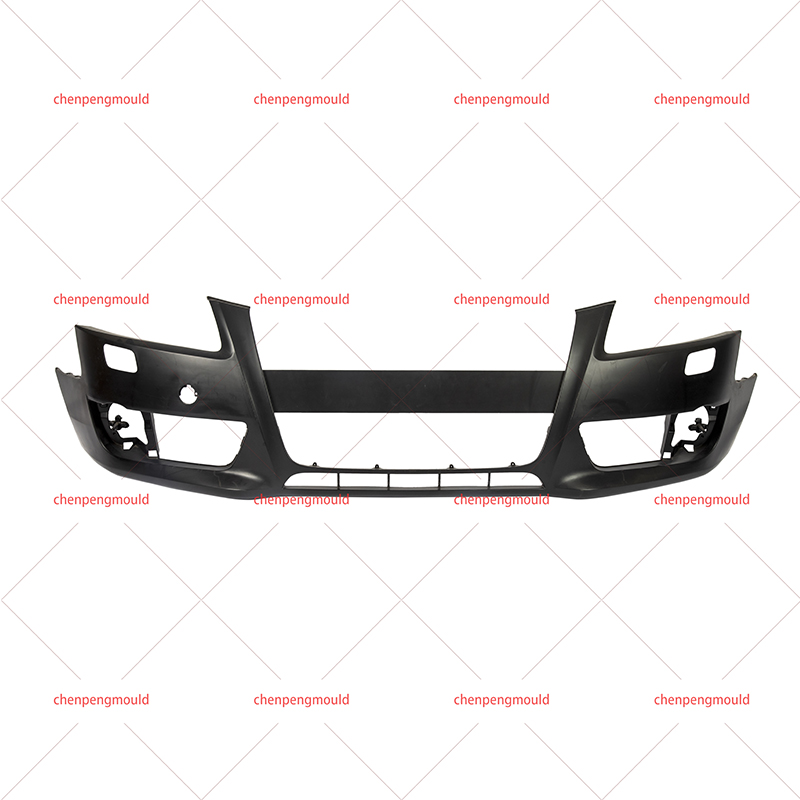

Lower Grill Molding: A Crucial Component

Lower Grill Molding, as an integral part of the overall assembly, undergoes a specialized manufacturing process. The grill molding is intricately designed to provide both protection and aesthetic enhancement to the vehicle's lower grill area. The molding process involves precise cutting, shaping, and detailing to create a seamless integration with the vehicle's design. Its role extends beyond visual appeal, as it also provides structural support to the lower grill, reinforcing its durability and longevity.

The Marriage of Form and Function

Stainless Steel Bumper Molding and Lower Grill Molding exemplify the successful marriage of form and function in automotive manufacturing. The use of stainless steel as the primary material ensures not only a visually appealing finish but also long-lasting durability against the elements. The meticulous manufacturing process, from material selection to quality control, guarantees that each component meets the highest standards, contributing to the overall excellence of the vehicle.

Conclusion

The production of Stainless Steel Bumper and Lower Grill Molding is a multi-faceted journey that combines advanced manufacturing technologies with skilled craftsmanship. The emphasis on stainless steel as the material of choice underscores the commitment to durability and aesthetic refinement.

+86-18357617666

+86-18357617666