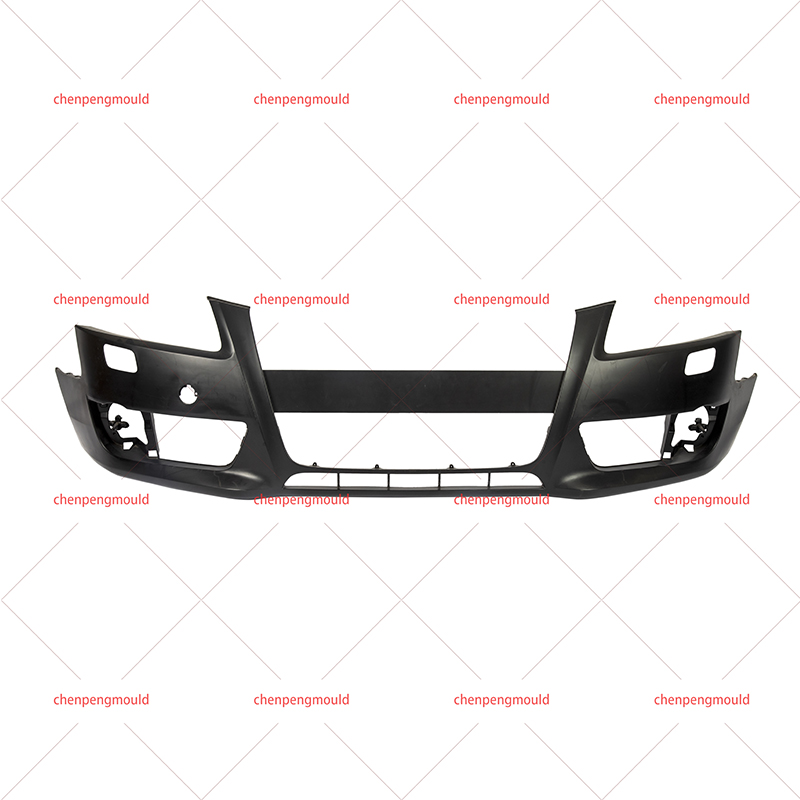

As a part of the vehicle's exterior design, the plastic material used in the car's front bumper has unique characteristics, which not only affects the aesthetic appearance, but also affects the overall safety and performance of the car.

The choice of car front bumper material is crucial to the performance of the vehicle. This is not only because the front bumper is directly affected by collisions and the environment, but also because its material needs to maintain stability and reliability in various weather conditions and road conditions.

With the continuous advancement of technology, engineering plastics are widely used in the manufacture of automobile front bumpers. These plastics offer excellent strength, heat resistance and corrosion resistance, making them an ideal material choice for front bumpers.

Lightweight designs are commonly used in the automotive manufacturing industry to improve fuel efficiency and reduce exhaust emissions. Using a lightweight Automotive Bumper Plastic Type helps achieve this while ensuring the front bumper is still strong enough to handle a collision.

Front bumpers need to have excellent impact resistance to absorb energy during a collision and reduce the impact of the impact on the vehicle and passengers. Specially designed plastic materials can deform during a collision, thereby effectively slowing down the transfer of collision energy.

Car front bumpers are exposed to various weather conditions, so their materials need to have good weather resistance. The weather-resistant plastic material prevents color fading, aging and brittleness, ensuring that the front bumper maintains good appearance throughout its service life.

Front Bumper Material is not static, but varies depending on the manufacturer and model. Common plastic materials include polypropylene (PP), polycarbonate (PC), polyamide (PA), etc., each of which has unique properties and characteristics.

In today's pursuit of sustainability, recyclability has become an important consideration in material selection. The use of recyclable plastic materials helps reduce resource waste and is in line with the green development concept of the automobile manufacturing industry.

The flexibility of plastic materials allows automakers to achieve a greater variety of color customization and appearance effects. This provides car designers with greater creative space to make the vehicle's appearance more creative and personalized.

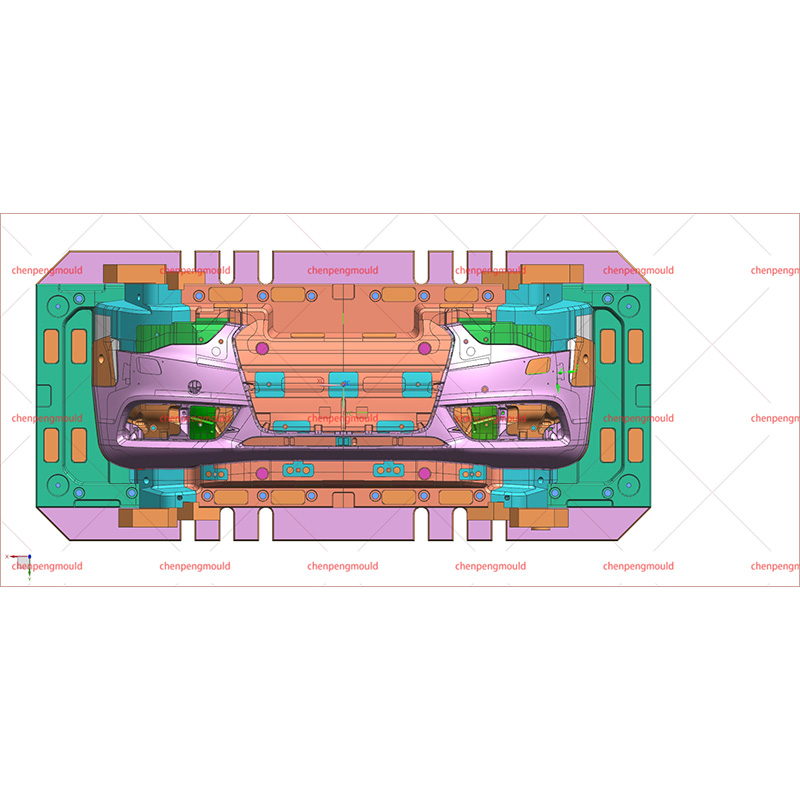

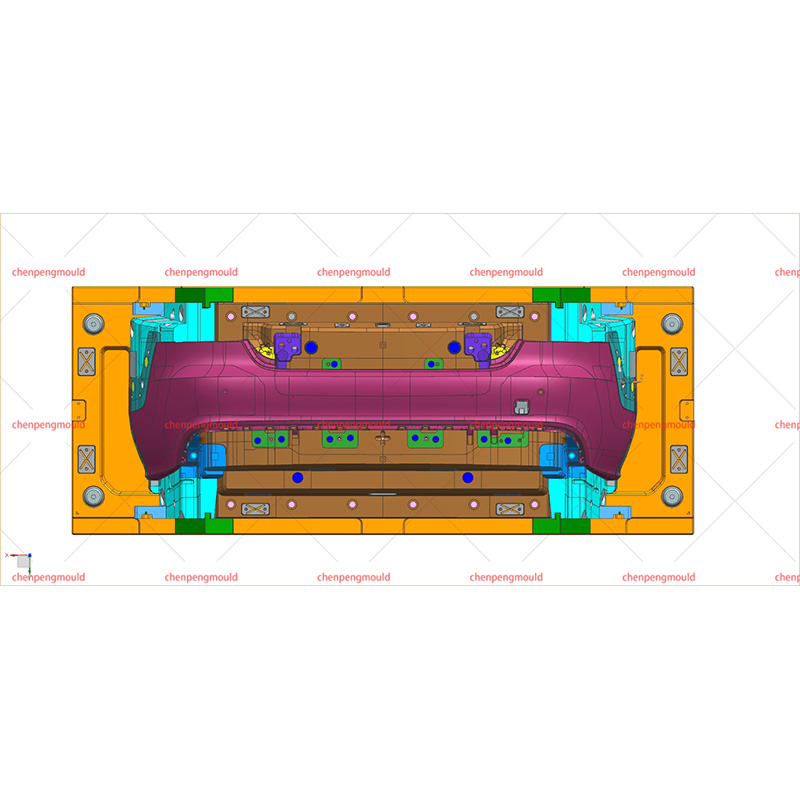

Different Automotive Bumper Plastic Types require different manufacturing processes. Injection molding is a common manufacturing process that creates the shape of the front bumper by injecting molten plastic into a mold, ensuring a consistent and high-quality finished product.

Last but not least, the front bumper material needs to meet safety standards. This includes testing the material's crashworthiness and flame retardancy to ensure that the front bumper can protect the vehicle and passengers in an accidental collision.

The plastic material used in automobile front bumpers is special because it not only needs to meet strict safety standards, but also needs to adapt to the automobile manufacturing industry's pursuit of lightweight and environmental protection. The selection of Automotive Bumper Plastic Type has become an important factor that cannot be ignored in automobile design, and is directly related to the performance and appearance design of the vehicle.

+86-18357617666

+86-18357617666