Plastic auto parts play a crucial role in the automotive manufacturing industry, contributing significantly to various applications within the sector. These components have become integral to modern vehicles, providing numerous benefits in terms of design, efficiency, and sustainability.

Interior Automotive Applications:

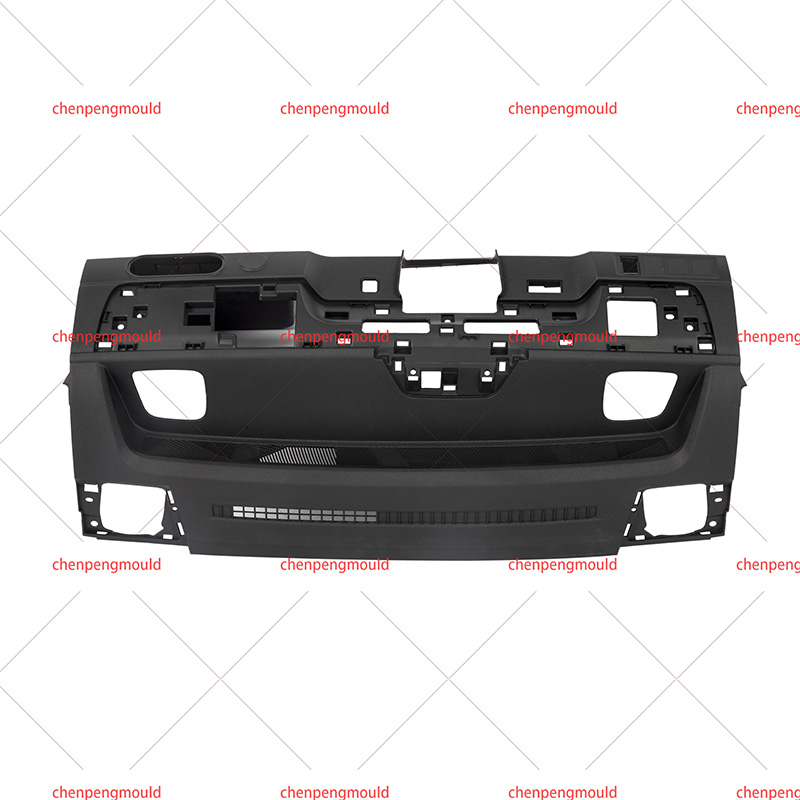

1. Dashboard Components:

Plastic auto parts are commonly used in the manufacturing of dashboard components. This includes the dashboard itself, instrument panels, and various controls. The lightweight nature of plastic contributes to improved fuel efficiency and enhances overall vehicle performance.

2. Interior Trim and Panels:

The interior aesthetics of a vehicle are often enhanced by the use of plastic components for trim and panels. These parts provide a high degree of design flexibility, allowing manufacturers to create stylish and ergonomic interiors.

3. Seats and Seat Components:

Certain seat components, such as seat backs and frames, are also made from durable plastics. This not only reduces the weight of the vehicle but also ensures that these components are resistant to wear and tear, thereby increasing their lifespan.

4. Storage Compartments:

Plastic is widely utilized in the creation of storage compartments within the vehicle. Center consoles, glove boxes, and door pockets are examples of areas where plastic auto parts contribute to the functional and aesthetic aspects of vehicle interiors.

5. Air Conditioning and Ventilation Systems:

Plastic components are often integrated into the air conditioning and ventilation systems of vehicles. Ducts, vents, and other parts benefit from the material's resistance to corrosion and its ability to withstand temperature variations.

Exterior Automotive Applications:

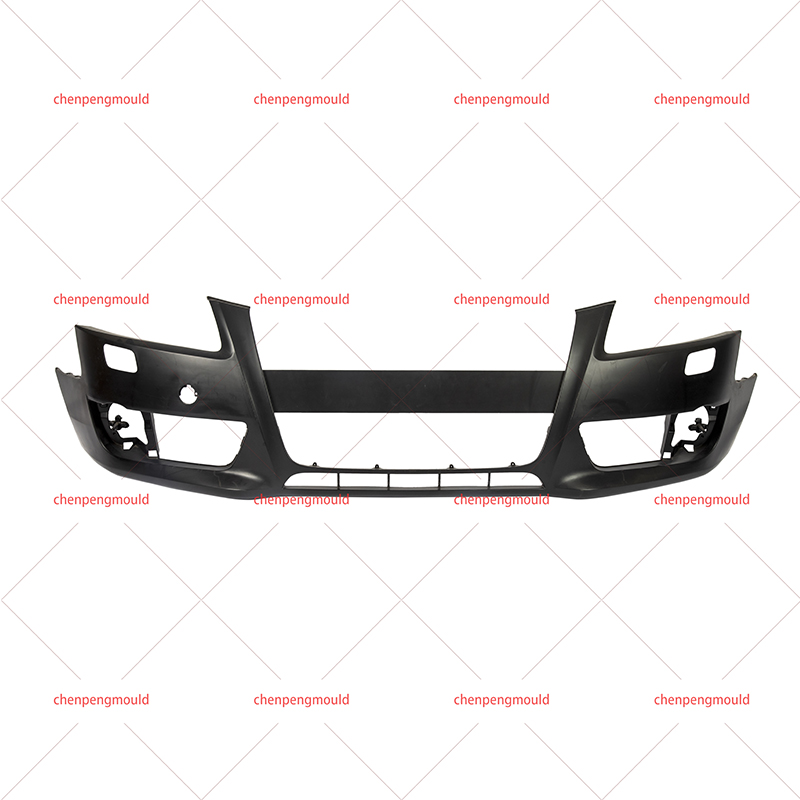

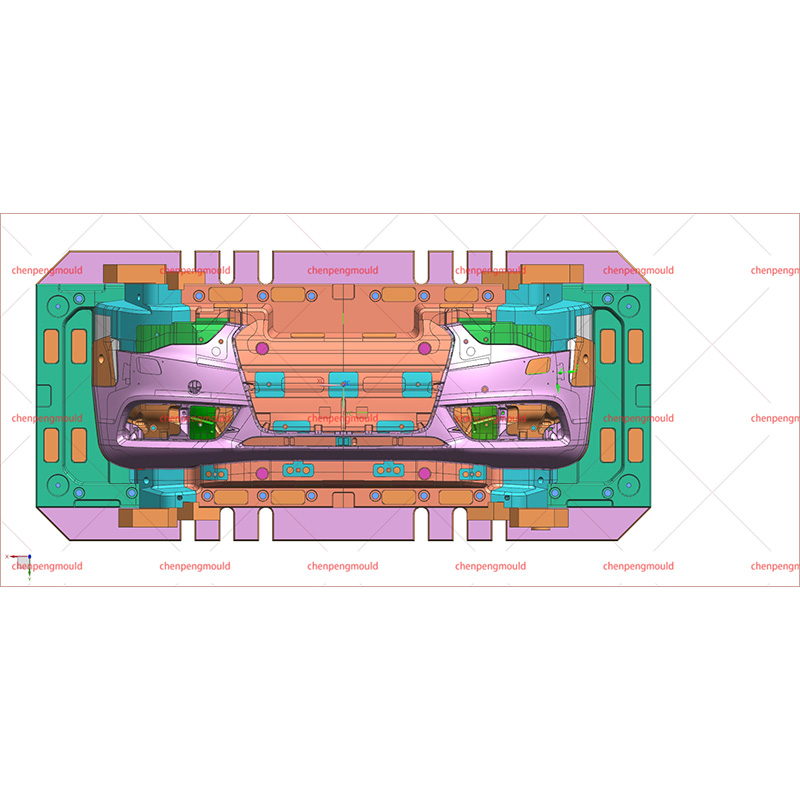

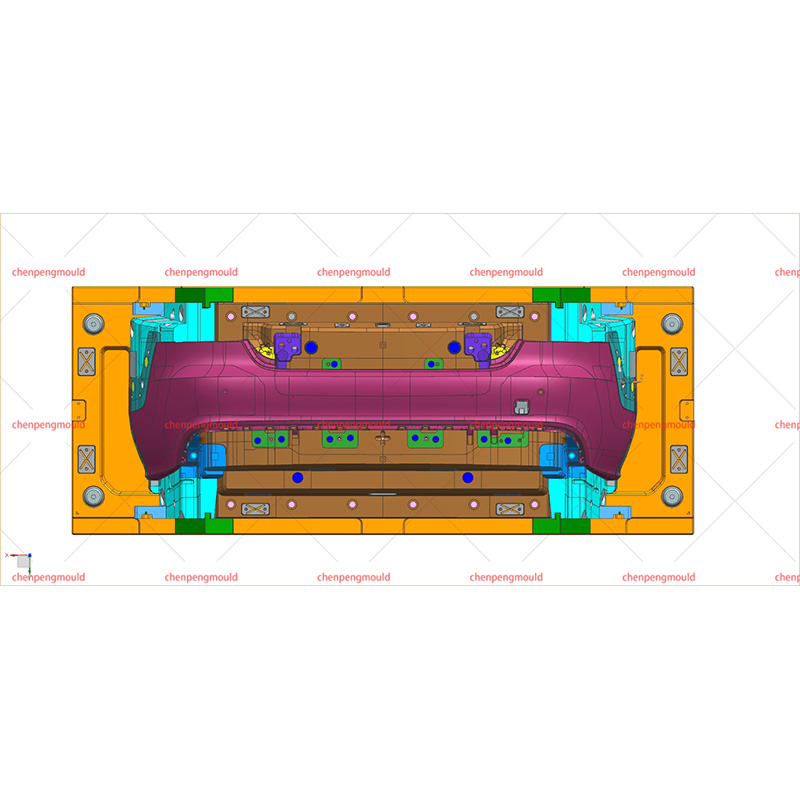

1. Bumpers and Body Panels:

Plastic auto parts are extensively used in the manufacturing of bumpers and body panels. These components enhance the overall safety of the vehicle by absorbing impact energy during collisions. The use of plastics also contributes to improved fuel efficiency due to reduced overall weight.

2. Grilles and Exterior Trim:

The exterior appearance of a vehicle is often enhanced by the incorporation of plastic grilles and trim. Manufacturers utilize plastic's versatility to create intricate and stylish designs that contribute to the vehicle's aesthetic appeal.

3. Headlights and Taillights:

Many modern vehicles feature plastic components in their headlights and taillights. The use of plastic in these areas allows for intricate designs, and it is a durable material that can withstand exposure to various weather conditions.

4. Side Mirrors:

Plastic auto parts are commonly employed in the manufacturing of side mirrors. The lightweight nature of plastic contributes to reduced aerodynamic drag, positively impacting fuel efficiency.

5. Exterior Moldings and Decals:

Moldings and decals on the exterior of vehicles are often made from plastic materials. This allows for customization options, and the durability of plastic ensures that these elements can withstand exposure to the elements.

The plastic auto parts play a pivotal role in both the interior and exterior aspects of automotive design and manufacturing. From enhancing vehicle aesthetics to improving fuel efficiency and safety, the widespread application of plastic components has become a hallmark of modern automotive engineering. The continual innovation in plastic materials and manufacturing processes ensures that these components will remain essential in shaping the future of the automotive industry.

+86-18357617666

+86-18357617666