China Sale Wholesale Auto Parts Mould Manufacturer Factory

In the fast-paced and ever-evolving world of automotive manufacturing, efficiency and reliability are of paramount importance. This is where wholesale auto parts moulds play a significant role. These molds not only optimize production processes but also ensure consistent and precise manufacturing of auto parts.

1. What are wholesale auto parts molds?

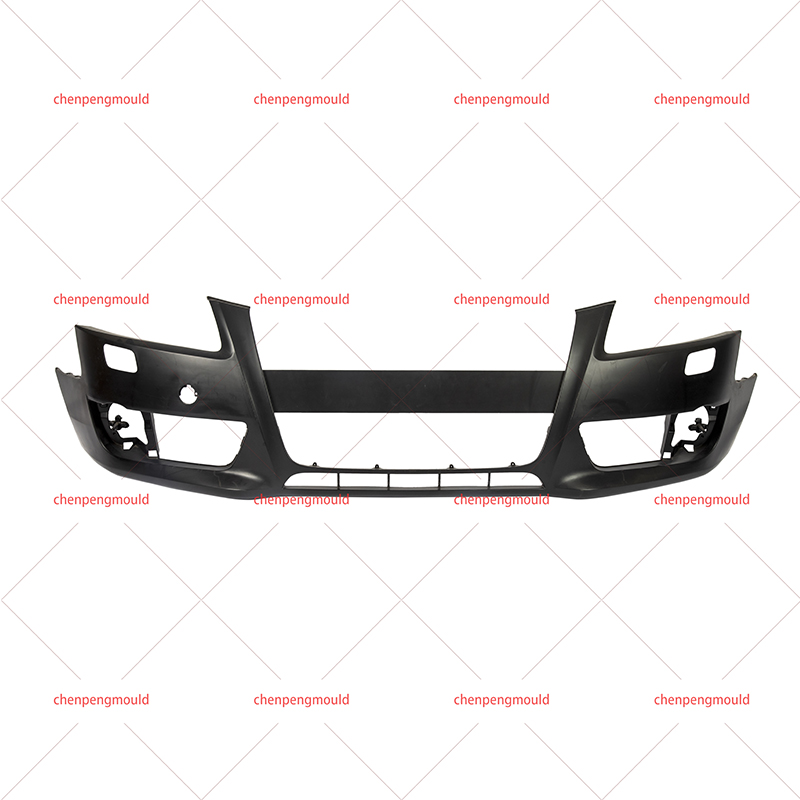

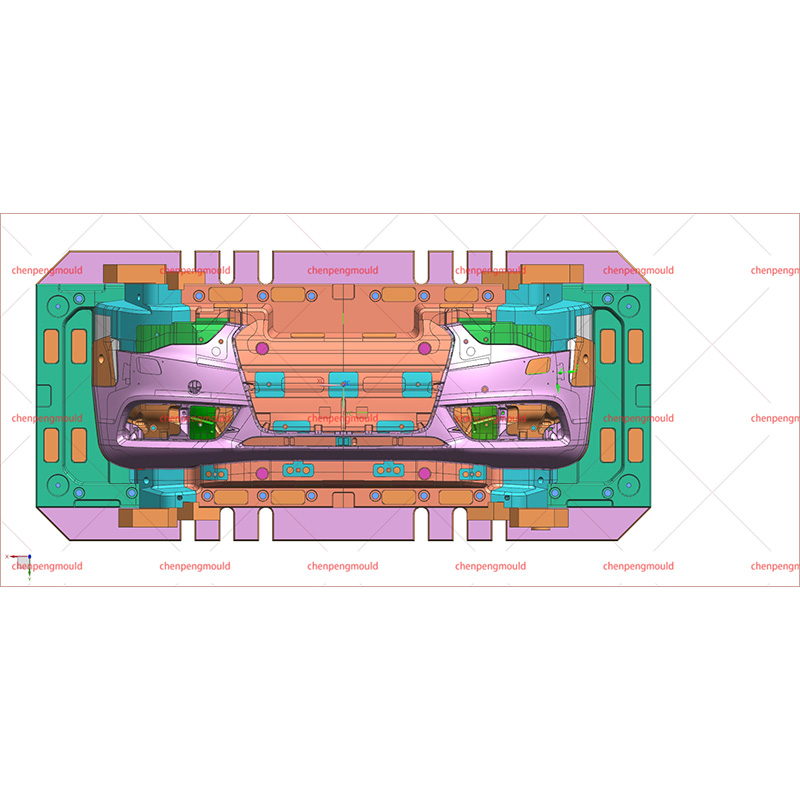

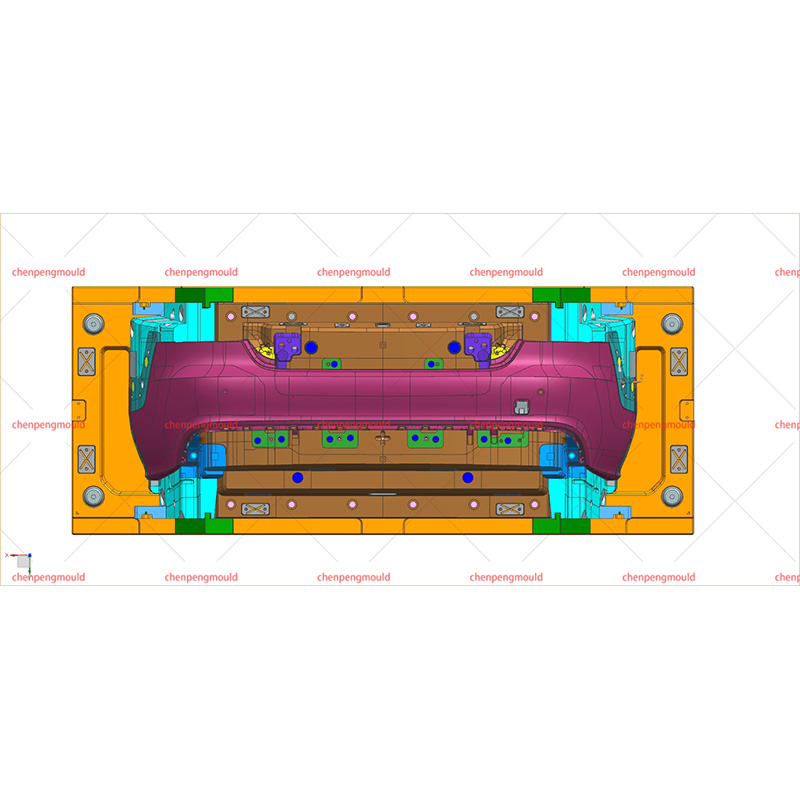

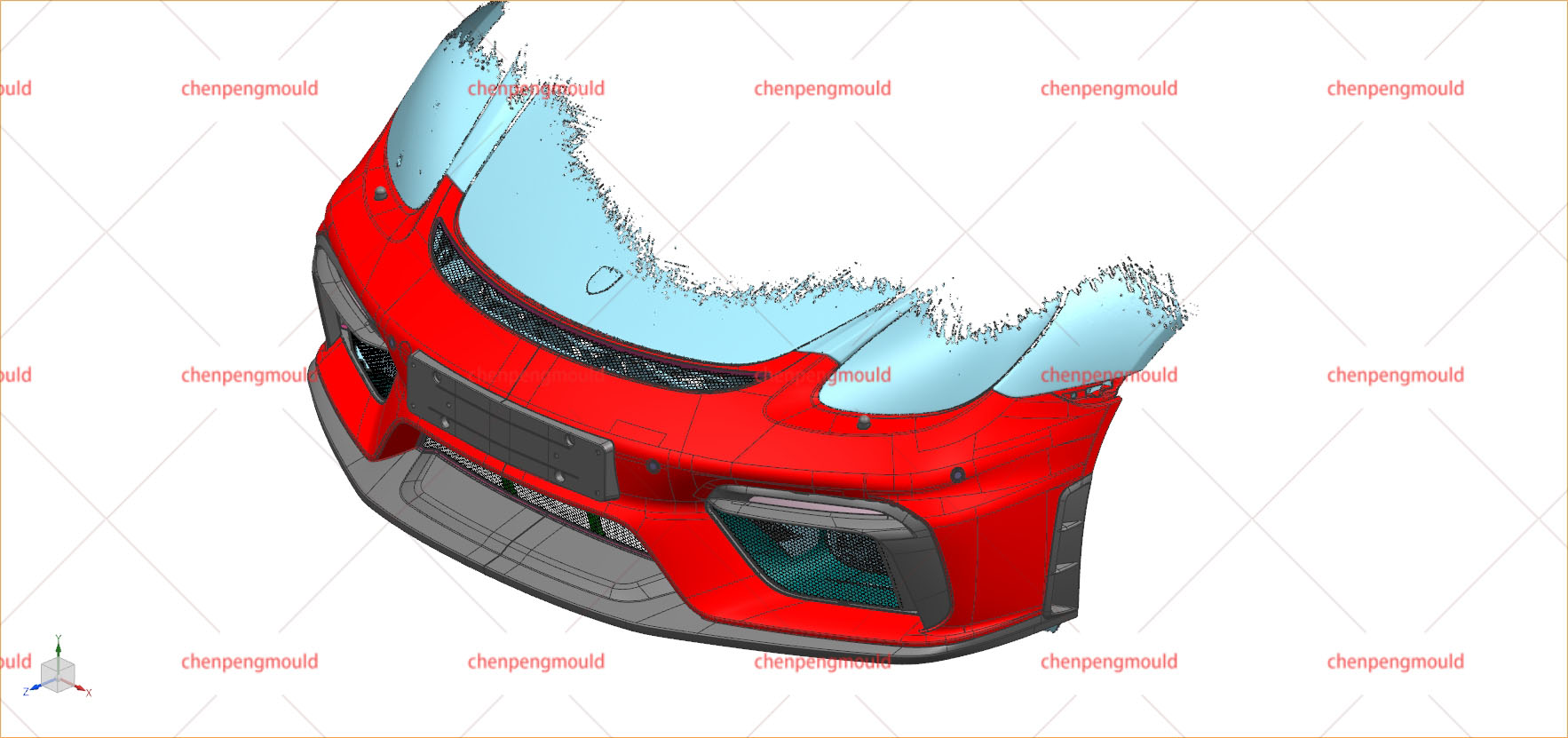

Wholesale auto parts molds are specialized tools, often made of high-quality materials such as steel or aluminum. They are specifically designed to shape and form various auto parts during the manufacturing process. These molds are crucial in ensuring the accuracy, quality, and consistency of automotive components.

2. Why are wholesale auto parts molds essential in the automotive industry?

In the automotive industry, precision and uniformity in the manufacturing process are of utmost importance. Wholesale auto parts molds provide the necessary precision, resulting in consistent and reliable production of auto parts. By employing these molds, manufacturers can ensure that each part meets the required specifications, guaranteeing a high level of quality control.

3. How do wholesale auto parts molds optimize production processes?

Wholesale auto parts molds offer several advantages when it comes to streamlining production processes:

a) Increased efficiency: These molds enhance the efficiency of the manufacturing process by reducing the time required for manual shaping and forming of auto parts. With the use of molds, manufacturers can produce parts at an accelerated rate, resulting in higher productivity.

b) Cost-effective production: By utilizing wholesale auto parts molds, manufacturers can reduce labor costs associated with manual shaping. The molds enable automated production, minimizing the need for manual. This not only saves time but also reduces production costs, making it a cost-effective solution for automotive manufacturers.

c) Consistency and uniformity: Wholesale auto parts molds ensure uniformity in the production process by providing consistent shaping and forming of each auto part. This helps eliminate variations and defects that could occur through manual processes, ensuring a higher-quality end product.

4. What are the key considerations when selecting wholesale auto parts molds?

Choosing the right wholesale auto parts molds for your manufacturing needs is crucial for achieving good results. Consider the following factors:

a) Material: The material used to build the molds is critical. It must be durable, heat resistant, and able to withstand repetitive use without deterioration. Steel and aluminum molds are popular choices due to their sturdiness and longevity.

b) Complexity of parts: Consider the complexity of the auto parts you want to manufacture. Ensure that the molds you select can adequately replicate the intricacies and details required. Precision is essential to ensure that every part meets the necessary specifications.

c) Mold lifespan: Assess the expected lifespan of the molds you plan to purchase. Quality molds, when properly maintained, can last for several years, resulting in long-term savings for the manufacturer.

d) Mold maintenance: Proper maintenance of wholesale auto parts molds is crucial for their longevity and good performance. Choosing molds that are easy to clean, repair, and maintain can save both time and resources.

5. What are the benefits of using high-quality wholesale auto parts molds?

Investing in high-quality wholesale auto parts molds offers several benefits to automotive manufacturers:

a) Improved productivity: By reducing the time required for manual shaping and forming, these molds significantly enhance production efficiency, resulting in increased output and productivity.

b) Enhanced quality control: Wholesale auto parts molds ensure consistent production, minimizing variations and defects. This, in turn, improves overall product quality and customer satisfaction.

c) Cost savings: The automated production process facilitated by these molds reduces labor costs in the long run. Additionally, the high durability of quality molds saves costs associated with mold replacements.

d) Precise replication: High-quality molds can replicate intricate details with accuracy, ensuring that each auto part conforms precisely to the required specifications.

+86-18357617666

+86-18357617666