China Automotive Front Bumper Molds Custom Price OEM Company

The automotive industry is a testament to the relentless pursuit of innovation and precision. One of the critical components that contribute to the aesthetics, safety, and functionality of vehicles is the automotive bumper. The technology behind China Automotive Bumper Mold is a fascinating blend of engineering, design, and manufacturing prowess.

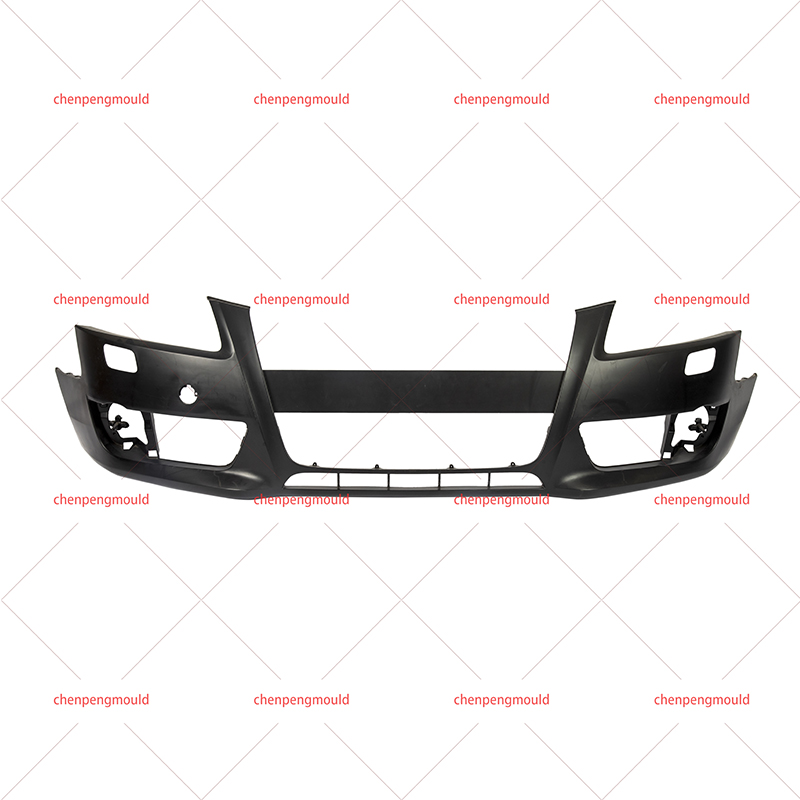

Automotive bumpers are not merely decorative elements; they serve a crucial role in the safety and structural integrity of vehicles. They are designed to absorb impact during collisions, thereby protecting the vehicle's occupants and reducing damage to the car. The design and construction of automotive bumpers have evolved significantly over the years, with China Automotive Bumper Mold playing a pivotal role in this advancement.

The Evolution of Bumper Mold Technology

The history of automotive bumpers dates back to the early 20th century when they were simple metal plates. However, with the advent of new materials and manufacturing techniques, the design and functionality of bumpers have improved dramatically. China Automotive Bumper Mold has been at the forefront of this evolution, consistently pushing the boundaries of what is possible in bumper design and production.

Material Innovations

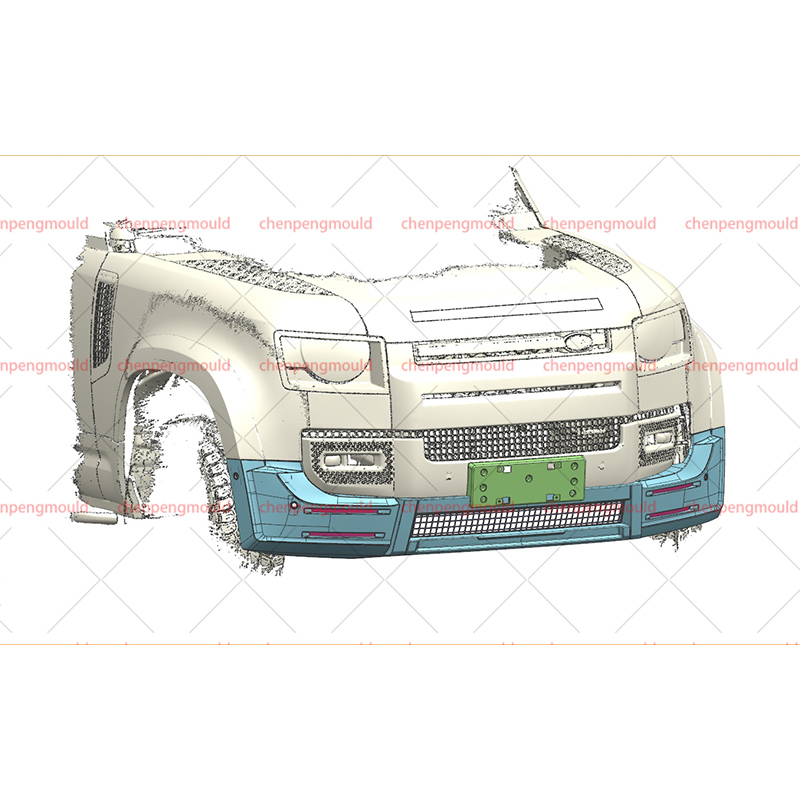

One of the significant advancements in China Automotive Bumper Mold technology has been the introduction of new materials. Traditionally, bumpers were made from steel, but modern bumpers often incorporate a combination of metals, plastics, and composite materials. These materials are lighter, more durable, and can be molded into more complex shapes, which is essential for the intricate designs of today's vehicles.

Design Flexibility

The flexibility offered by China Automotive Bumper Mold technology has allowed designers to create bumpers that are not only functional but also visually appealing. The molds can be designed to produce bumpers with intricate details, curves, and contours that enhance the overall aesthetics of the vehicle.

Safety Enhancements

Safety is a paramount concern in the automotive industry, and China Automotive Bumper Mold has played a significant role in improving the safety features of bumpers. Modern bumpers are designed to crumple and absorb impact during collisions, reducing the force transmitted to the vehicle's occupants. The precision engineering of China Automotive Bumper Mold ensures that these safety features are consistently and reliably incorporated into each bumper.

The Manufacturing Process of China Automotive Bumper Mold

The process of creating a China Automotive Bumper Mold is a complex and highly specialized task. It involves several stages, each of which requires precision and expertise.

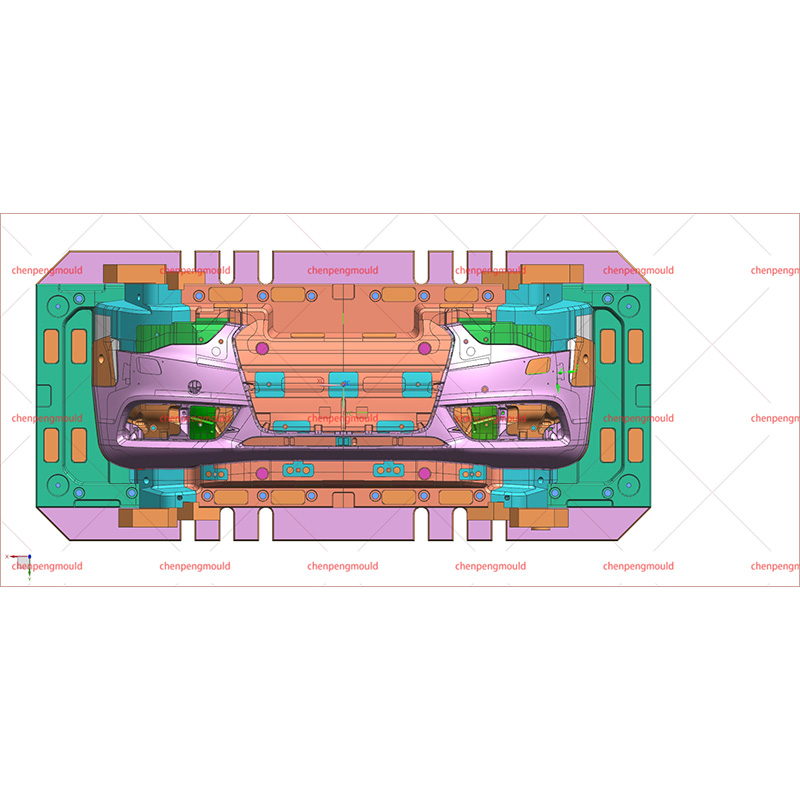

Design and Engineering

The step in the manufacturing process is the design and engineering of the mold. This involves creating a 3D model of the bumper, which is then used to design the mold itself. The design must take into account the material to be used, the desired shape and features of the bumper, and the specific requirements of the vehicle it will be fitted to.

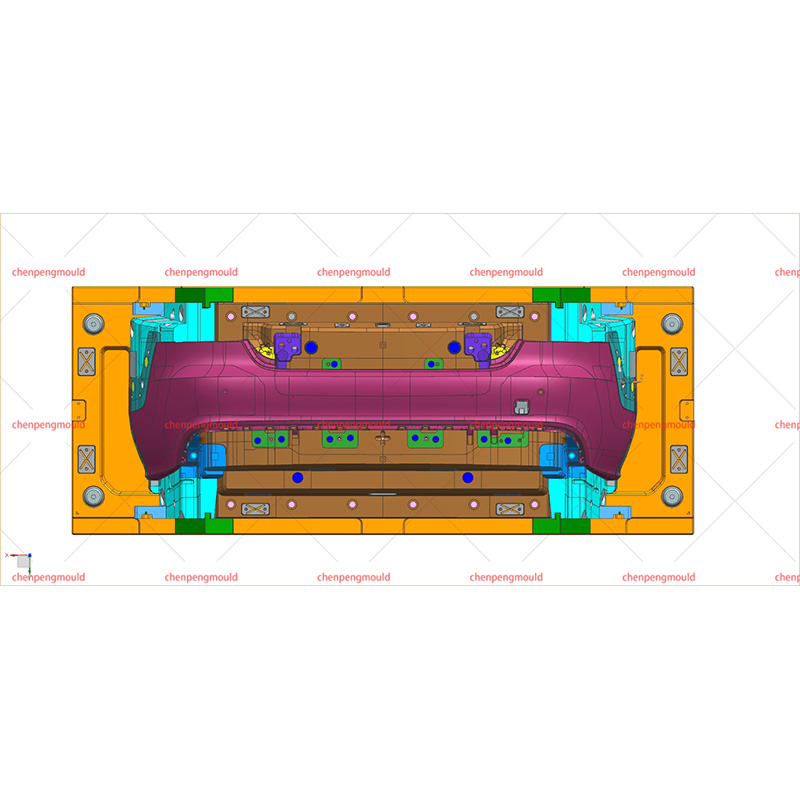

Tooling and Machining

Once the design is finalized, the tooling and machining process begins. This involves creating the physical mold that will be used to shape the bumper. High-precision CNC machines are often used in this process to ensure that the mold is accurate and consistent.

Material Selection and Injection

With the mold ready, the next step is the selection of the appropriate material for the bumper. This can include a variety of materials, such as polypropylene, which is commonly used due to its durability and flexibility. The material is then heated and injected into the mold.

Cooling and Ejection

After the material has been injected into the mold, it needs to cool and solidify. This is a critical step, as it ensures that the bumper maintains its shape and integrity. Once the material has cooled, the mold opens, and the bumper is ejected.

Finishing and Quality Control

The final stage in the manufacturing process is the finishing and quality control. This involves inspecting the bumper for any defects, trimming any excess material, and applying any necessary coatings or treatments. The bumper is then tested to ensure that it meets the required safety and performance standards.

+86-18357617666

+86-18357617666