China Automotive Front Bumper Molds For Sale Maker Wholesaler

The automotive industry is a powerhouse of innovation, where design and engineering come together to create vehicles that are not only functional but also aesthetically pleasing. One of the critical components in a vehicle's design is the automotive bumper, which plays a significant role in both the safety and visual appeal of the car. The journey of an automotive bumper mold, particularly from China Automotive Bumper Mold, is a fascinating exploration of precision, innovation, and the intricate process that transforms a concept into a tangible part of millions of vehicles worldwide.

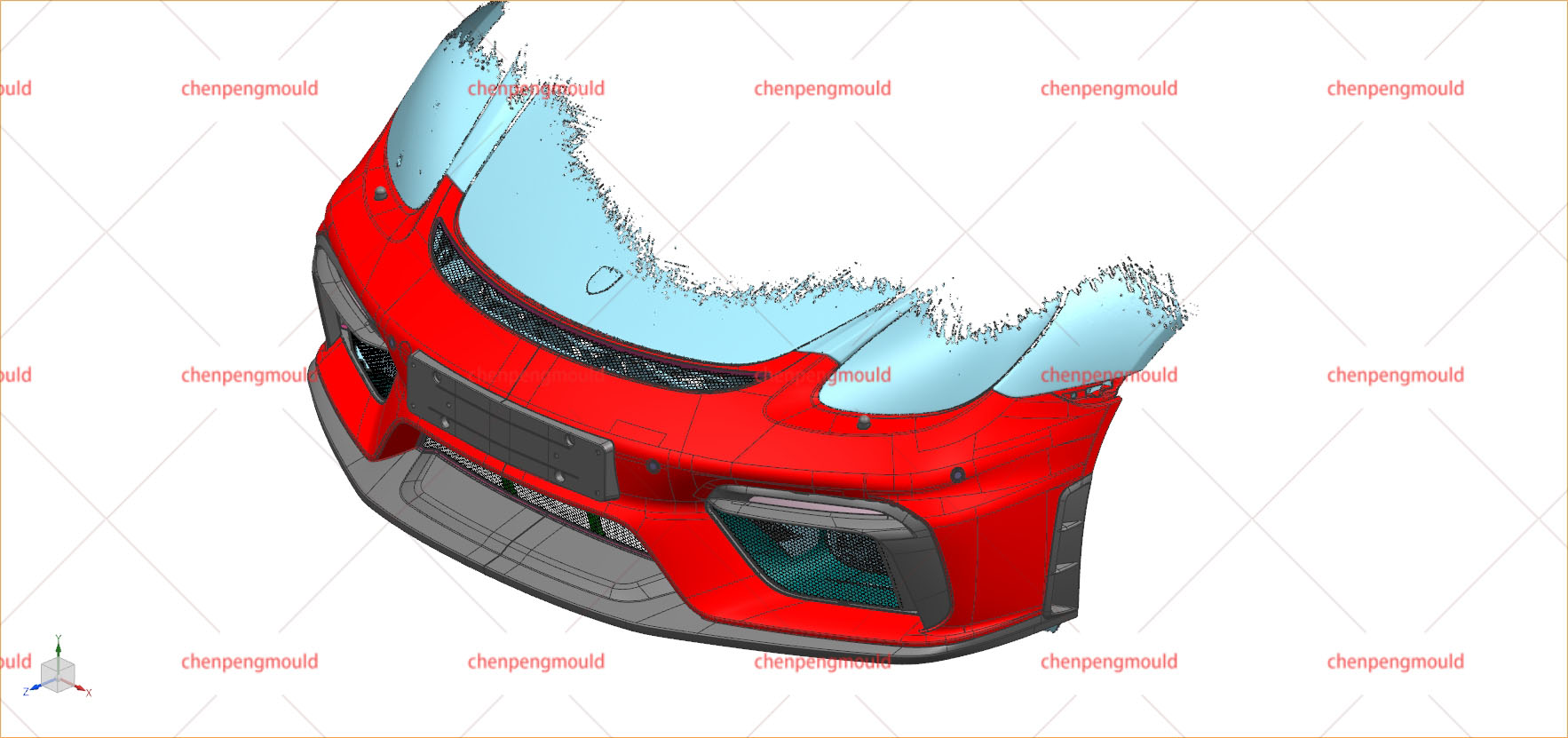

The journey of a China Automotive Bumper Mold begins with a concept. Designers and engineers collaborate to create a bumper that not only meets safety standards but also aligns with the vehicle's overall design language. This phase involves extensive research and development to ensure that the bumper mold will be able to withstand the rigors of the road while complementing the vehicle's style.

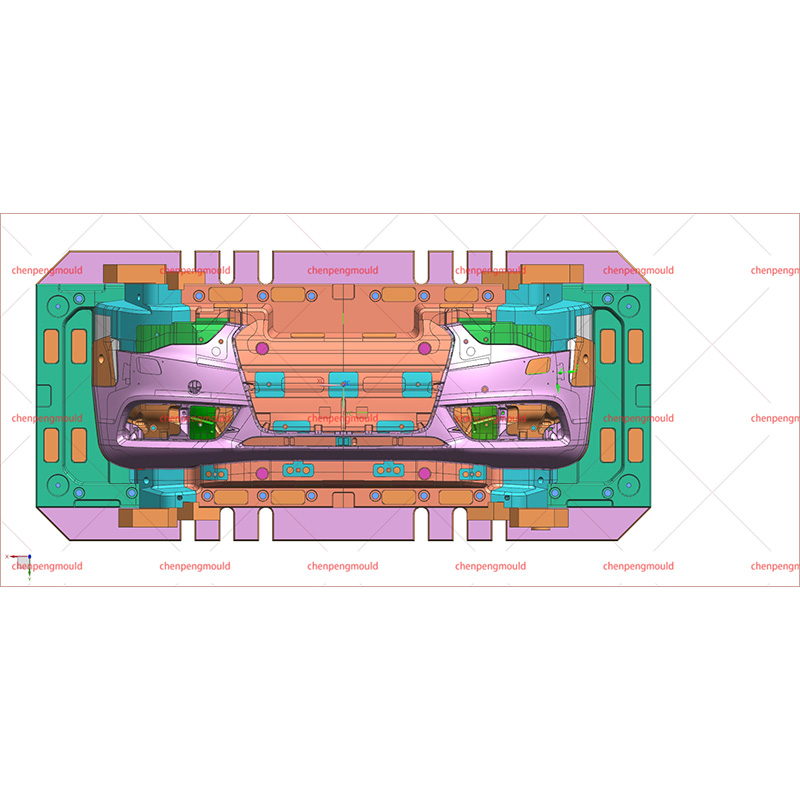

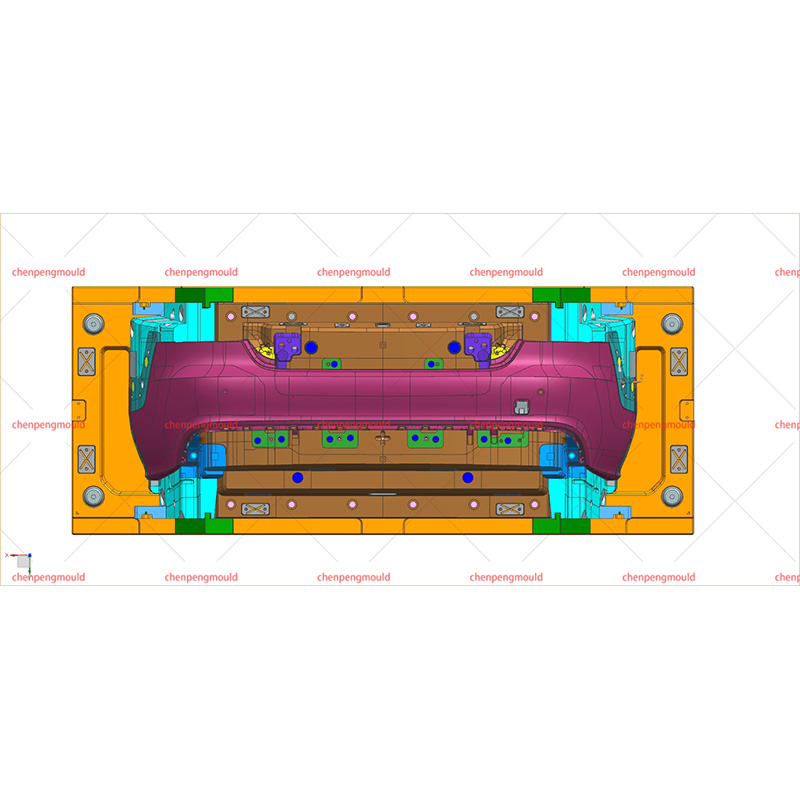

Once the concept is approved, the design and engineering phase commences. This is where the China Automotive Bumper Mold truly starts to take shape. Designers use advanced computer-aided design (CAD) software to create detailed 3D models of the bumper. These models are then analyzed and tested for structural integrity, impact resistance, and aerodynamics.

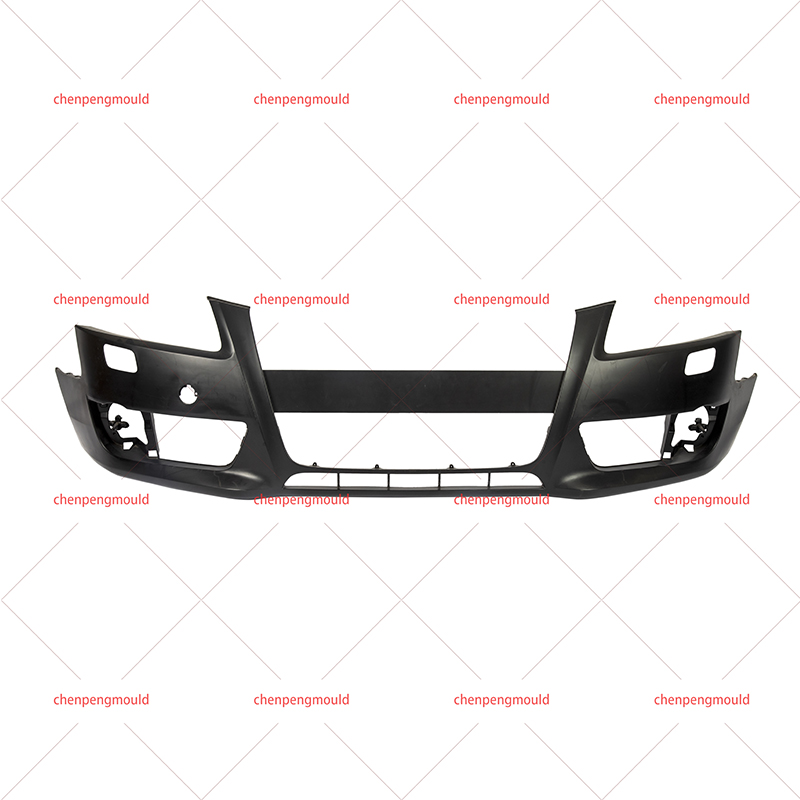

With a finalized design, the process moves to the creation of the China Automotive Bumper Mold. This involves the production of tooling and molds that will be used to shape the bumper during manufacturing. The mold-making process is highly specialized and requires precision engineering to ensure that the final product meets the exact specifications of the design.

The choice of material for the China Automotive Bumper Mold is crucial. Materials must be selected based on their durability, flexibility, and ability to withstand various weather conditions. Common materials include high-strength plastics, composites, and metals. The selection process is meticulous, ensuring that the chosen material will not only perform well but also contribute to the overall safety and efficiency of the vehicle.

The next step in the journey of a China Automotive Bumper Mold is the injection molding process. This is where the selected material is heated and then injected into the mold under high pressure. The mold is designed to have specific cavities and cores that give the bumper its shape and features. Once the material has cooled and solidified, the mold is opened, and the bumper is carefully removed.

No China Automotive Bumper Mold leaves the factory without undergoing rigorous quality control and testing. This ensures that each bumper meets the standards of quality, durability, and performance. Testing may include impact tests, durability tests, and visual inspections to ensure that there are no defects or inconsistencies in the final product.

Once the bumper has passed all quality control checks, it is ready for assembly and integration into the vehicle. This process involves attaching the bumper to the vehicle's chassis and ensuring that it aligns with the rest of the car's body. The assembly process is carried out with precision to maintain the structural integrity and aesthetic appeal of the vehicle.

The journey of a China Automotive Bumper Mold is heavily reliant on advanced technology. From the initial design phase to the final assembly, technology plays a crucial role in ensuring that the bumper mold is produced to the standards. This includes the use of CAD software, computer-aided manufacturing (CAM), and injection molding machines.

Precision is key in the production of China Automotive Bumper Molds. Each mold must be manufactured with exacting standards to ensure that the final product fits seamlessly with the vehicle's design and performs its safety functions effectively. Precision engineering is a hallmark of the automotive industry, and it is evident in every aspect of the bumper mold's journey.

+86-18357617666

+86-18357617666