ODM Car Bumper Injection Molding Price For Sale Company

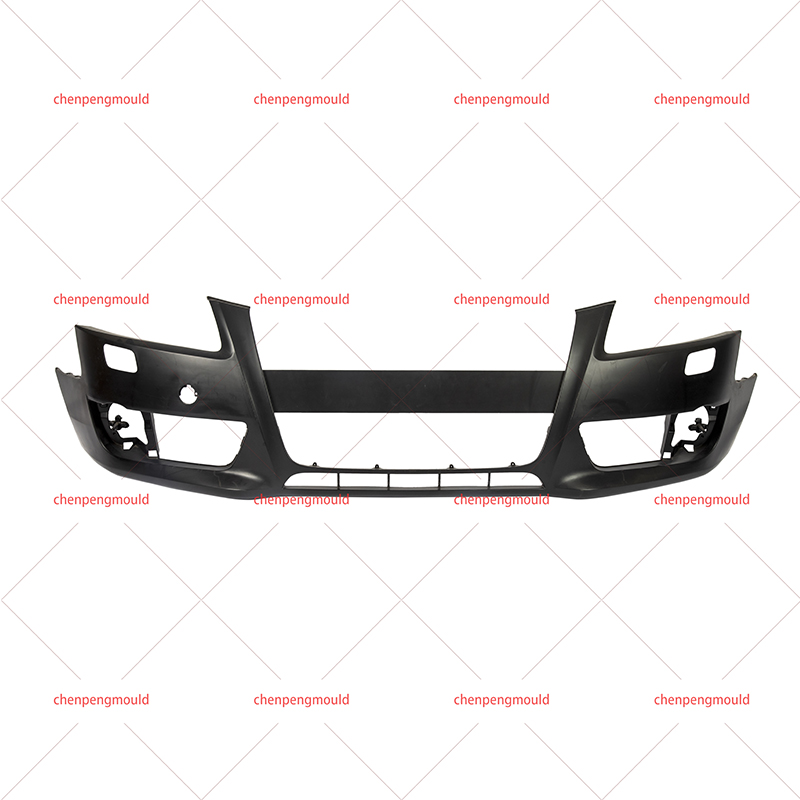

In the world of automotive manufacturing, efficiency and quality are paramount. Every component, no matter how small it may seem, plays a significant role in the overall performance and safety of a vehicle. One such component is the car bumper, which not only protects the vehicle's frame but also enhances its aesthetics. Achieving the desired quality and efficiency in car bumper production is made possible through a process known as car bumper injection molding.

Car bumper injection molding is a technique used in the manufacturing of car bumpers to ensure precise and consistent production. This process involves injecting molten plastic material into a mold cavity under high pressure, which allows it to take the shape of the desired car bumper design. The use of injection molding technology has revolutionized the automotive industry with its ability to produce intricate and complex parts with high accuracy and repeatability.

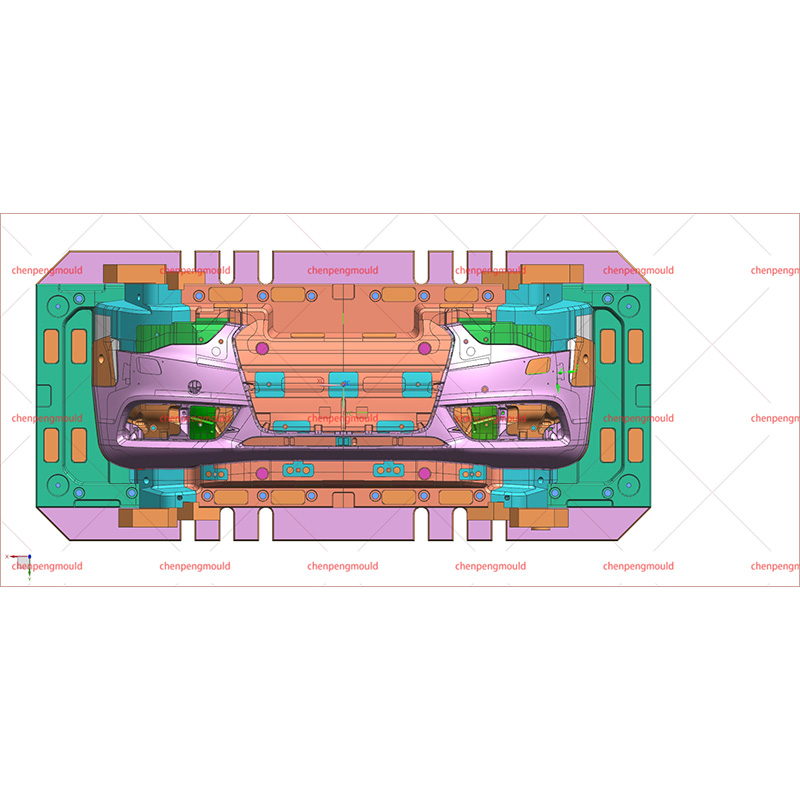

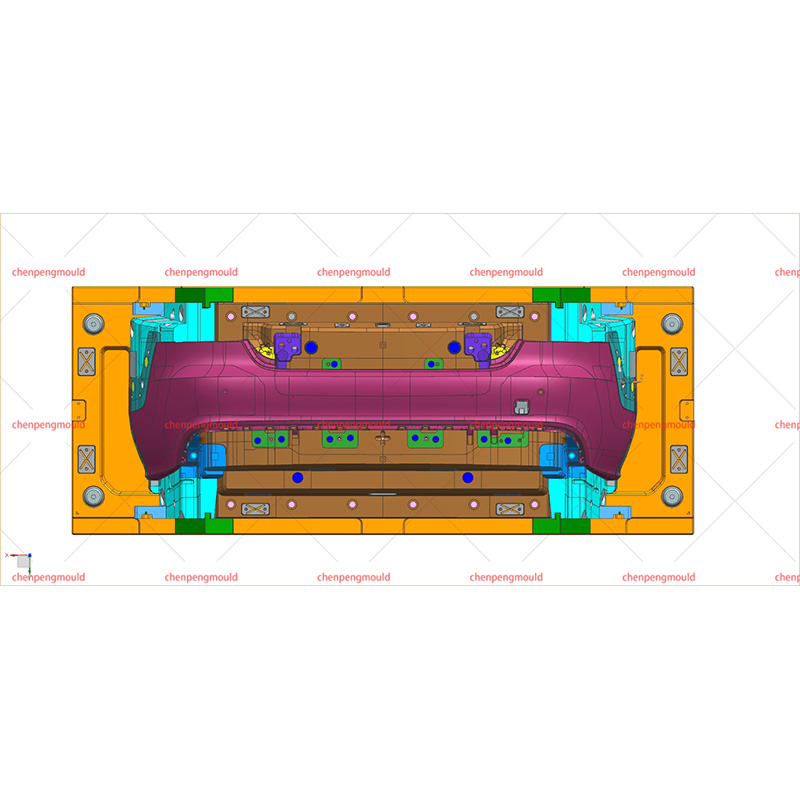

The process of car bumper injection molding begins with the design and development of the mold. Engineers and designers work together to create a detailed blueprint of the car bumper, taking into account factors such as material selection, part geometry, and production requirements. Once the design is finalized, the mold is created using advanced manufacturing techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM).

After the mold is ready, the injection molding process commences. The plastic material, typically polypropylene or polycarbonate, is fed into the injection molding machine's hopper. The material is heated to its melting point and then injected into the mold cavity using a reciprocating screw or plunger mechanism. The high pressure and temperature in the machine ensure that the molten plastic material fills every detail and corner of the mold, resulting in a precise and durable car bumper.

The car bumper injection molding process offers numerous advantages over traditional manufacturing methods. First and foremost, it allows for the production of complex bumper designs that would be difficult to achieve through other means. This means that car manufacturers can create unique and eye-catching bumper designs that differentiate their vehicles in the market.

Moreover, car bumper injection molding ensures a high level of accuracy and consistency in production. The molds used in the process are designed with precision, guaranteeing that each car bumper produced is identical in terms of dimensions and specifications. This uniformity is crucial in maintaining the quality and safety standards of the finished product.

Furthermore, car bumper injection molding allows for a high production rate and shorter cycle times. This means that car manufacturers can produce a large number of bumpers in a relatively short period, optimizing their overall production efficiency. Additionally, shorter cycle times boost productivity and help meet the increasing demand for automobiles in a timely manner.

Another benefit of car bumper injection molding is the cost-effectiveness it offers. The process minimizes material wastage, as the molten plastic is precisely injected into the mold, leaving little to no excess material. Additionally, the use of standardized molds and automated production systems reduces labor costs and eliminates the need for additional manual intervention.

In recent years, car bumper injection molding has witnessed further advancements with the adoption of innovative technologies. For instance, the integration of robotics and artificial intelligence (AI) in injection molding machines has led to improved process control and efficiency. These technologies enable real-time monitoring and adjustment of various parameters, ensuring consistent part quality and reducing the chances of defects.

However, it is essential to note that car bumper injection molding also faces certain challenges. One of the primary concerns is the environmental impact of plastic waste generated during the molding process. To address this issue, manufacturers are increasingly exploring the use of sustainable and recyclable materials. Additionally, efforts are being made to develop more efficient recycling methods for used car bumpers.

Car bumper injection molding plays a pivotal role in the automotive manufacturing industry. Its ability to produce precise and consistent car bumpers with high efficiency is vital for meeting the demands of the growing automotive market. As technology continues to advance, car bumper injection molding is expected to further evolve, offering even greater possibilities for innovation and sustainability in the automotive sector.

+86-18357617666

+86-18357617666