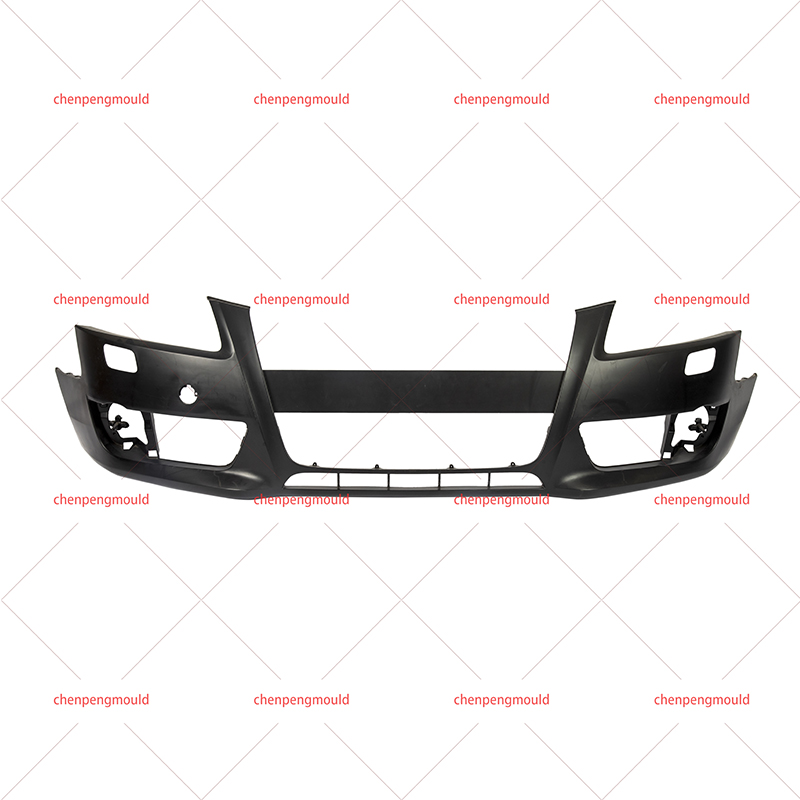

High Quality Car Bumper Molding Manufacturer Supplier Company

Car bumpers are vital components of every vehicle, serving as protective barriers during collisions, enhancing the vehicle's aesthetic appeal, and contributing to the overall structural integrity of the car. While people are familiar with the role bumpers play in protecting the car from low-speed impacts, fewer are aware of the complexities involved in manufacturing these critical parts. One key aspect of this manufacturing process is car bumper molding, a technique that shapes and forms bumpers using specialized molds.

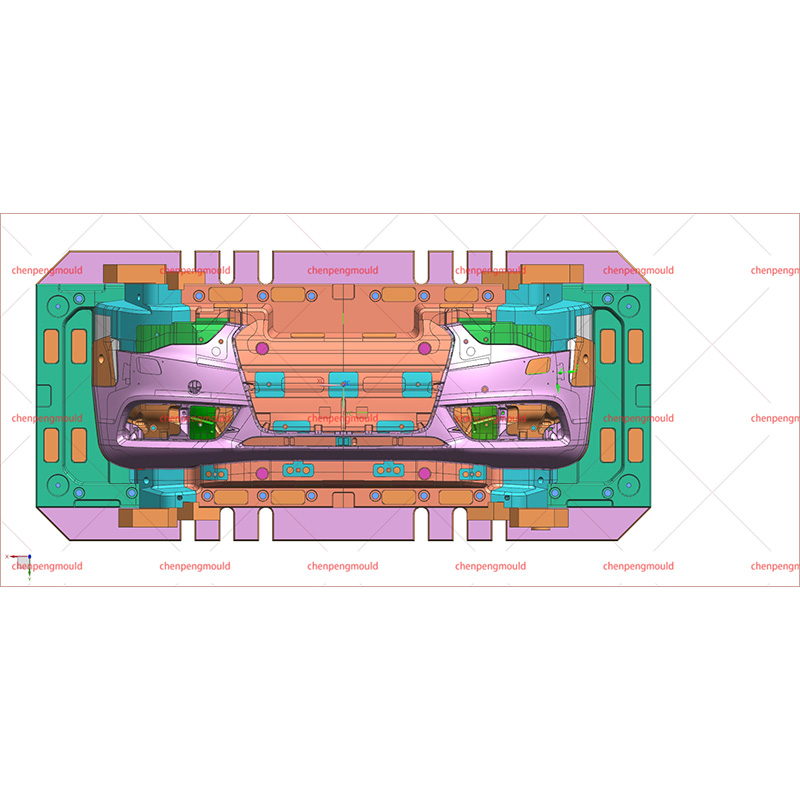

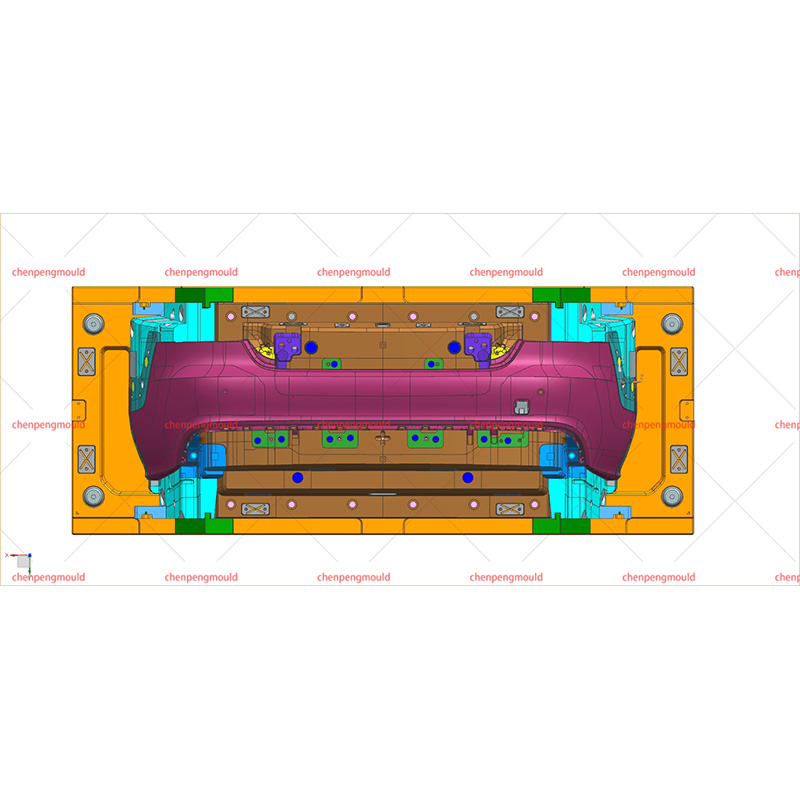

During the molding process, raw material is heated and injected or compressed into a mold cavity under high pressure, where it cools and solidifies into the shape of the bumper. This allows manufacturers to produce bumpers with precise dimensions, smooth surfaces, and the necessary strength to withstand impact forces.

The Role of Bumper Molding in Vehicle Safety

One of the primary functions of car bumper molding is ensuring that the vehicle’s bumper can absorb and distribute the impact of collisions, particularly low-speed impacts. Since bumpers are often the point of contact during minor accidents, they play a crucial role in damage to the vehicle and protecting the passengers.

1. Impact Absorption

Modern car bumpers are designed to absorb the kinetic energy of a collision, reducing the impact force that reaches the rest of the vehicle. Car bumper molding allows for the creation of bumpers that are strong yet flexible, enabling them to absorb energy efficiently without breaking or causing further damage. The material properties of the bumper—whether it’s polypropylene (PP), acrylonitrile butadiene styrene (ABS), or thermoplastic elastomers (TPE)—are optimized for impact resistance.

A well-molded bumper can help prevent damage to the vehicle’s frame, radiator, and other critical components, which may otherwise require expensive repairs after a minor collision.

2. Reinforcement Features

Bumper molding also allows for the integration of reinforcements like energy-absorbing foam or metal components that further enhance the bumper’s protective capabilities. These reinforcements are often embedded or molded into the bumper during manufacturing to provide additional strength and improve energy dissipation during an impact.

By controlling the mold design, manufacturers can create bumpers that offer more protection in certain areas while maintaining lighter weight or more aesthetic flexibility in others.

Enhancing Aesthetic Design and Customization

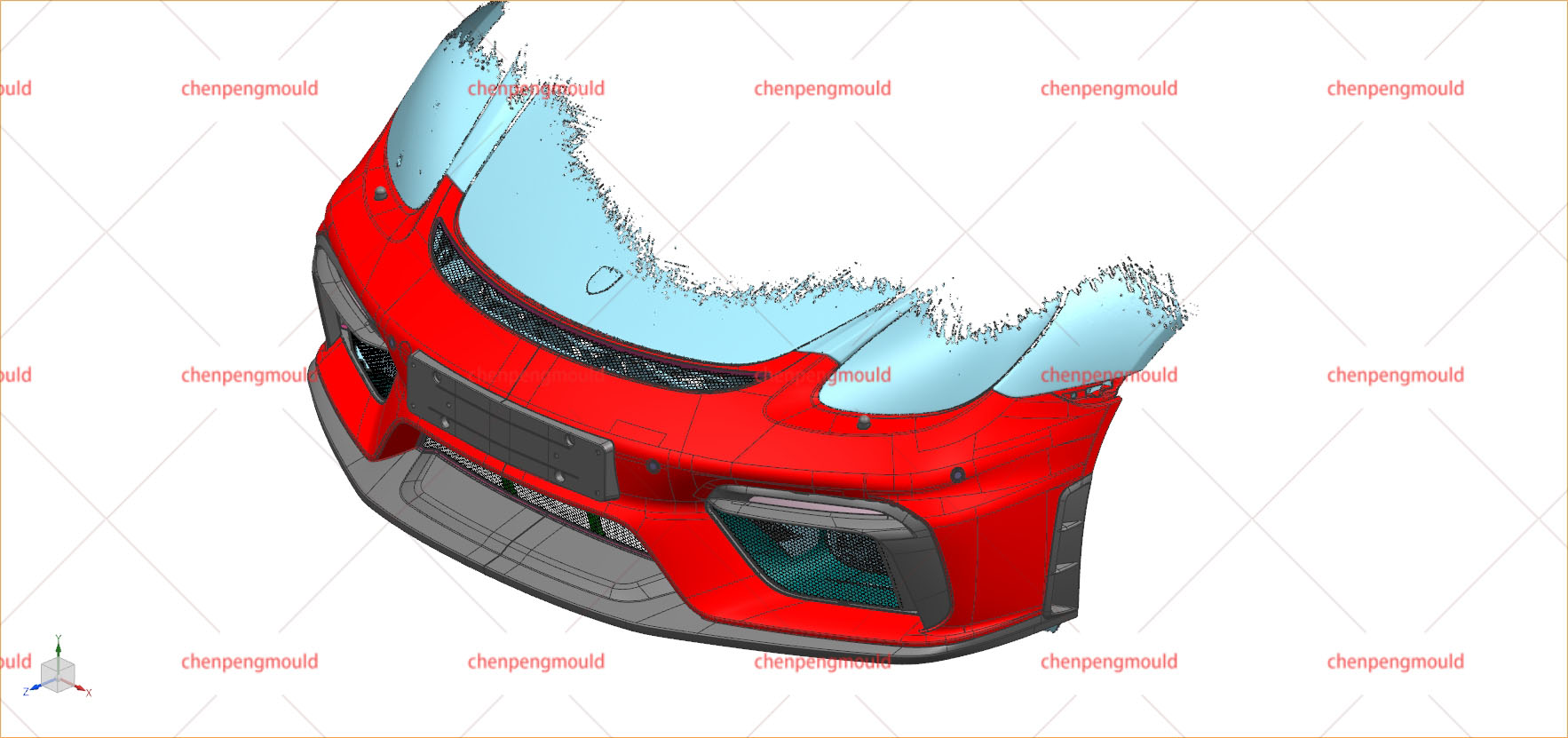

In addition to safety, car bumpers are also essential for the vehicle’s appearance. Bumper molding offers great design flexibility, allowing manufacturers to create bumpers that align with the overall style of the vehicle. From compact sedans to luxury cars and trucks, bumpers can be molded to suit various design themes, integrating features such as curves, contours, and aerodynamic elements.

1. Customized Designs

Car bumper molds allow manufacturers to achieve intricate designs that cannot be achieved by traditional fabrication methods. This capability enables custom shapes, integrated fog lights, sensors, and even specific branding elements, which enhance the visual appeal of the car while maintaining functionality.

This customization is also critical for ensuring that bumpers fit seamlessly into the car’s overall design. By using specialized molds, manufacturers can create bumpers that match the vehicle’s color scheme, integrate with the bodywork, and accommodate functional features like grilles, reflectors, and other accessories.

2. Integration of Technology

Bumper molding can also accommodate the integration of advanced technologies like parking sensors, cameras, and radar systems. Modern vehicles increasingly rely on these sensors for safety features such as adaptive cruise control and automatic emergency braking. The molding process ensures that the bumper can house these technologies without compromising their functionality or the overall appearance of the vehicle.

+86-18357617666

+86-18357617666