Front Bumper Molding For Cars Manufacturer Factory Supplier

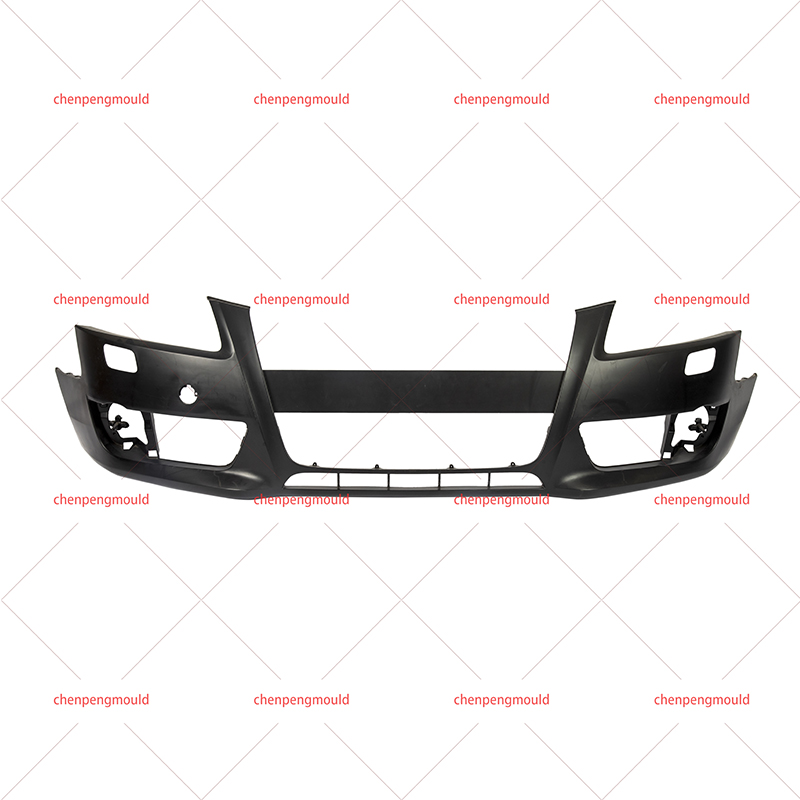

Bumper Molding For Cars is an essential component of a vehicle’s exterior design and functionality. It serves multiple purposes, including protecting the bumper from damage, enhancing the vehicle’s aesthetics, and improving the overall durability of the car’s front and rear ends. Bumper moldings come in various materials, designs, and finishes, making them a versatile and customizable addition for car owners.

Bumper moldings are commonly found on both the front and rear bumpers and are typically installed as part of the vehicle’s body trim package or as aftermarket accessories. They can be functional, aesthetic, or a combination of both, depending on the materials and design.

Types of Bumper Molding for Cars

There are several types of bumper moldings, each designed to cater to different vehicle models and requirements. Below are the common types, along with their features and benefits:

1. Plastic Bumper Molding

Plastic bumper moldings are one of the popular and commonly used types of moldings for vehicles. They offer a combination of affordability, durability, and versatility. These moldings are typically made from high-impact plastic materials like ABS (Acrylonitrile Butadiene Styrene) or polypropylene, which provide strength and flexibility. Plastic moldings can be found in various finishes, such as matte, glossy, or textured, and are available in a range of colors, including black, chrome, and body-matched colors.

Advantages:

Lightweight and cost-effective

Resistant to corrosion and rust

Available in various finishes and colors for customization

Easy to install, often with adhesive backing or clips

Disadvantages:

May crack or break under severe impact

Not as durable as metal moldings in weather conditions

Can fade or discolor over time, especially when exposed to UV rays

2. Rubber Bumper Molding

Rubber bumper molding is designed primarily for impact absorption and is often used in environments where the vehicle is prone to collisions, such as city driving or parking in tight spaces. Rubber moldings are flexible and can absorb shock, protecting the bumper from minor impacts and scratches. These moldings are typically made from high-quality, durable rubber compounds or thermoplastic elastomers, making them both flexible and resilient.

Advantages:

Durable and resistant to cracking or splitting

Helps reduce noise when hitting obstacles

Suitable for vehicles that frequently park in tight spaces

Disadvantages:

Can be more expensive than plastic moldings

Rubber can deteriorate over time due to exposure to UV rays and temperatures

May require more frequent maintenance, such as cleaning or conditioning

3. Chrome Bumper Molding

Chrome bumper molding is a popular option for those who want to add a touch of luxury or sportiness to their vehicle. Chrome moldings are made of either stainless steel or plastic that has been coated with a chrome finish, giving the vehicle a shiny, reflective look. Chrome bumper moldings are especially popular on high-end cars, trucks, and SUVs, as they add an elegant, polished appearance.

Advantages:

Adds a high-end, shiny look to the vehicle

Resistant to rust and corrosion when made from stainless steel

Enhances the vehicle’s appearance and can make it stand out

Disadvantages:

Chrome can fade or tarnish over time if not properly maintained

Susceptible to scratches and can be challenging to repair if damaged

Typically more expensive than other types of bumper molding

Requires regular cleaning to maintain the glossy finish

+86-18357617666

+86-18357617666