High Quality China Automotive Bumper Mold Price For Sale Company

China Automotive Bumper Mold technology has witnessed remarkable advancements in recent years, reflecting the country's growing prowess in the automotive manufacturing sector. As China continues to emerge in automotive production, the development of innovative bumper mold technology plays a pivotal role in enhancing the efficiency, quality, and sustainability of vehicle manufacturing processes.

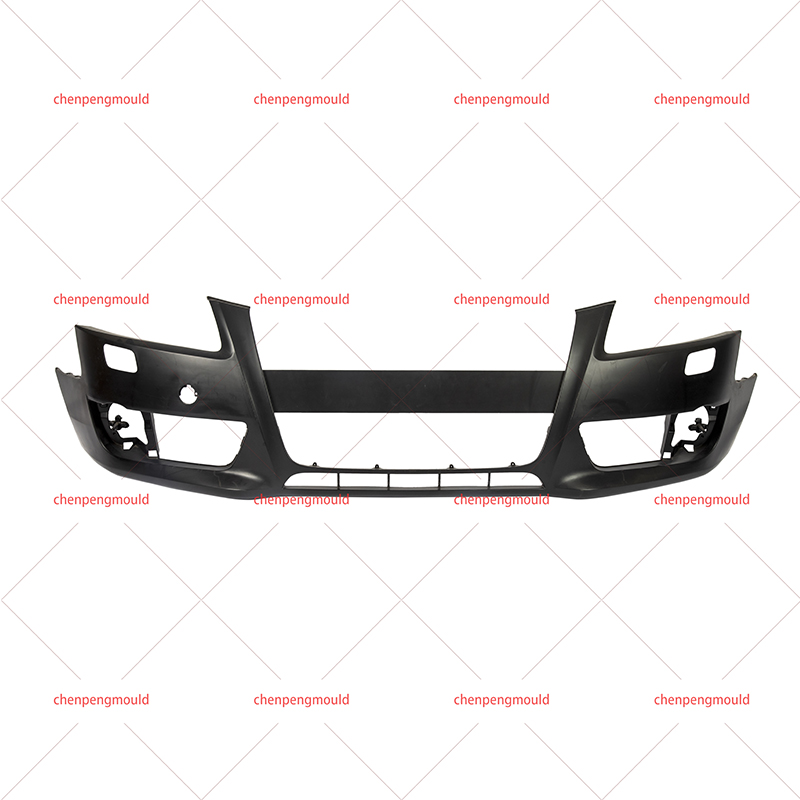

China Automotive Bumper Mold technology encompasses a wide range of techniques and methodologies aimed at designing and producing high-quality molds for automotive bumpers. These molds are essential components in the production of automotive bumpers, serving as the framework for shaping and molding the final product. With the right technology and expertise, China has become a hub for the development and production of automotive bumper molds that meet the stringent quality standards of the industry.

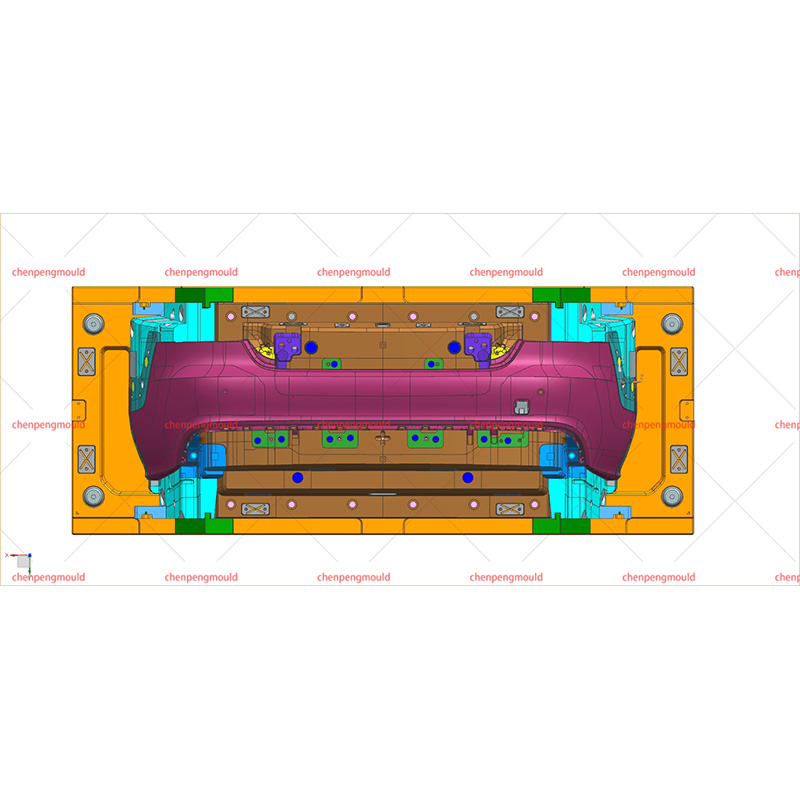

One of the key advancements in China Automotive Bumper Mold technology is the use of advanced materials and manufacturing techniques to improve the durability and performance of molds. Traditional molds were often made from metals such as steel or aluminum, which were heavy, costly, and prone to wear and tear over time. However, with the advent of new materials such as carbon fiber, composite plastics, and high-strength alloys, China has been able to produce lightweight yet durable molds that offer performance and longevity.

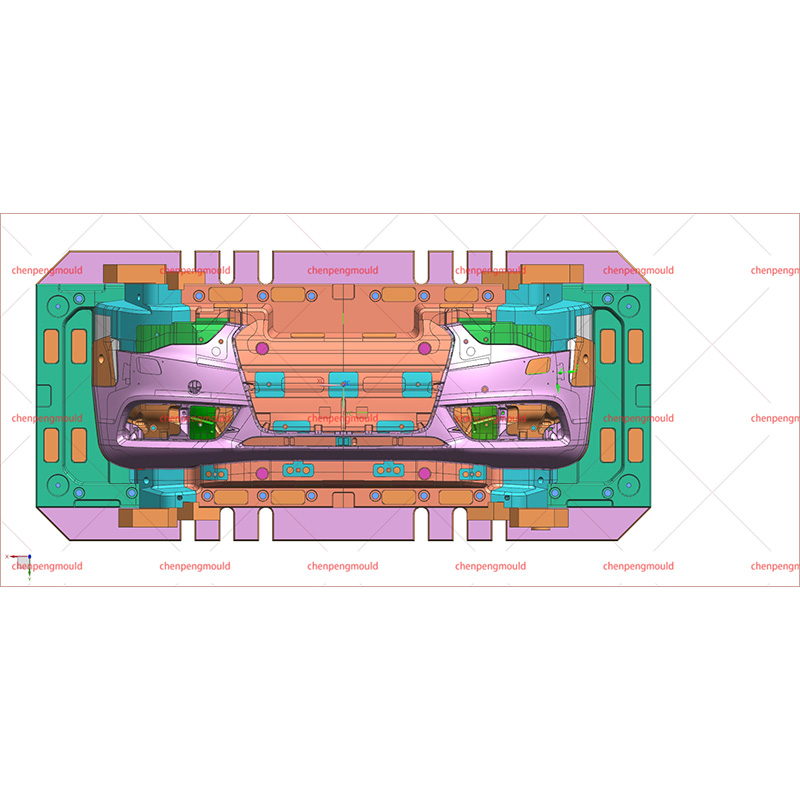

The adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has also revolutionized China Automotive Bumper Mold production. These advanced design and manufacturing tools allow engineers and technicians to create intricate and precise mold designs with accuracy and efficiency. By leveraging CAD/CAM technologies, China can produce molds with complex geometries and intricate features that were previously unattainable, enabling automakers to achieve greater design flexibility and innovation in their bumper designs.

In addition to advancements in materials and design, China Automotive Bumper Mold technology has also made significant strides in improving manufacturing processes and efficiency. Automation and robotics have been increasingly integrated into mold production facilities, streamlining workflows, reducing labor costs, and enhancing production speed and accuracy. Automated systems can perform tasks such as milling, cutting, and polishing with precision and consistency, resulting in higher-quality molds produced in less time and at lower cost.

Furthermore, China Automotive Bumper Mold technology has embraced sustainable manufacturing practices to reduce environmental impact and resource consumption. By optimizing material usage, minimizing waste generation, and implementing energy-efficient production processes. Additionally, the recycling and reuse of materials in mold production further contribute to the sustainability of the automotive manufacturing industry.

The automotive industry's shift towards electric and autonomous vehicles has also influenced China Automotive Bumper Mold technology. As automakers prioritize lightweight and aerodynamics to improve vehicle efficiency and performance, bumper mold designs have evolved to meet these demands. Advanced molding techniques such as injection molding and compression molding enable the production of lightweight yet durable bumper components that contribute to the overall efficiency and sustainability of electric and autonomous vehicles.

China's automotive bumper mold technology is not only driving innovation within the country but also shaping the global automotive industry. As China solidifies its position as the world's largest automotive market and manufacturing hub, the expertise and capabilities of its bumper mold technology are increasingly sought after by automakers worldwide. Chinese mold manufacturers are partnering with international automotive companies to develop cutting-edge mold solutions that meet the evolving needs of the global market.

+86-18357617666

+86-18357617666