Wholesale Custom China Automotive Bumper Mold Design Supplier

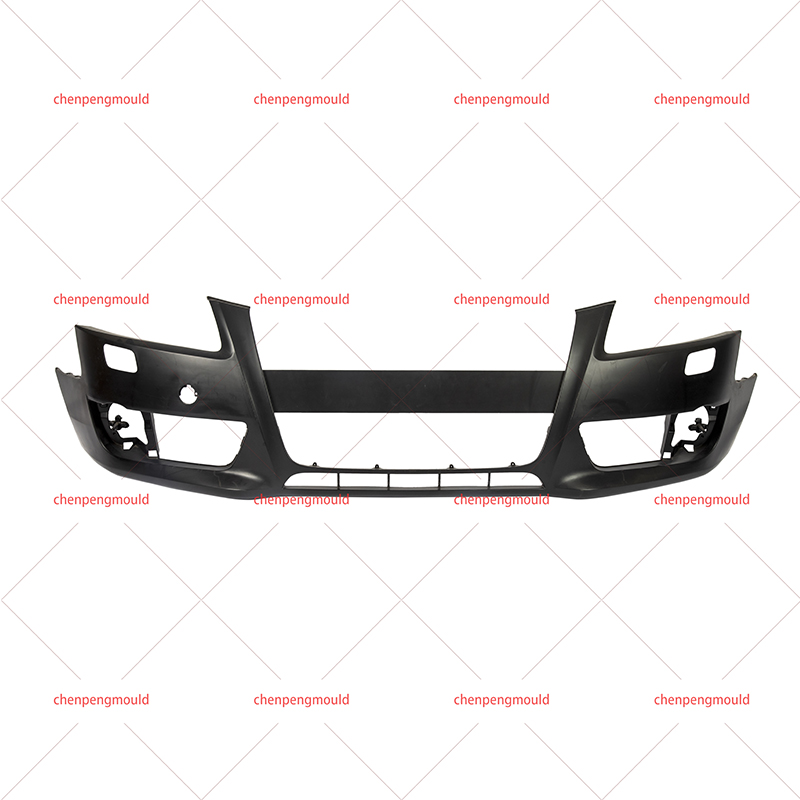

The automotive industry relies on a range of materials to create components that are both durable and precise. Among these components, the automotive bumper plays a crucial role in vehicle safety and design. China automotive bumper molds are essential in the production of these bumpers, and the materials used in their construction directly impact their effectiveness and longevity.

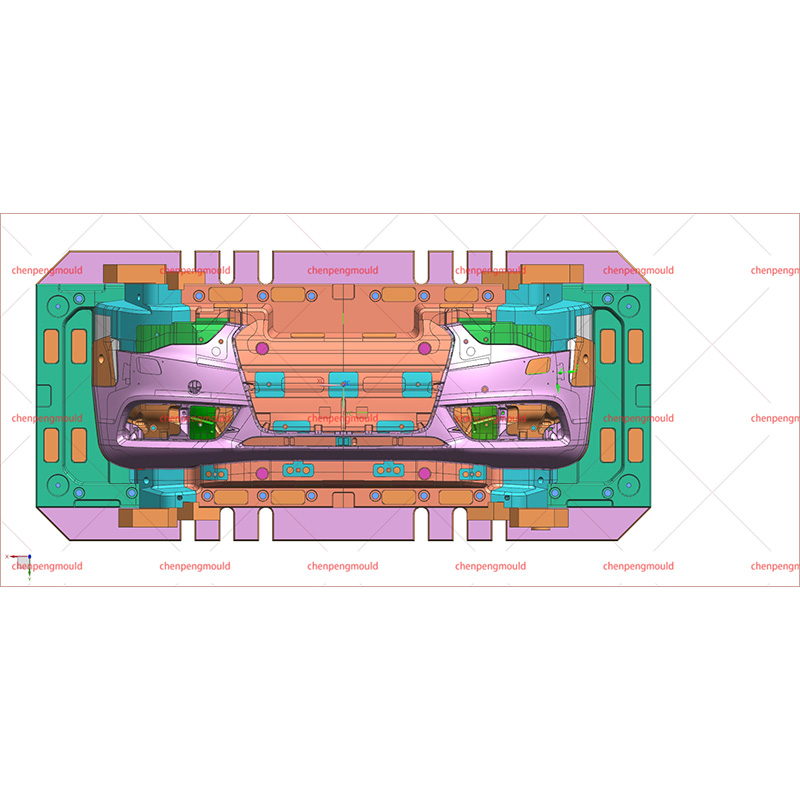

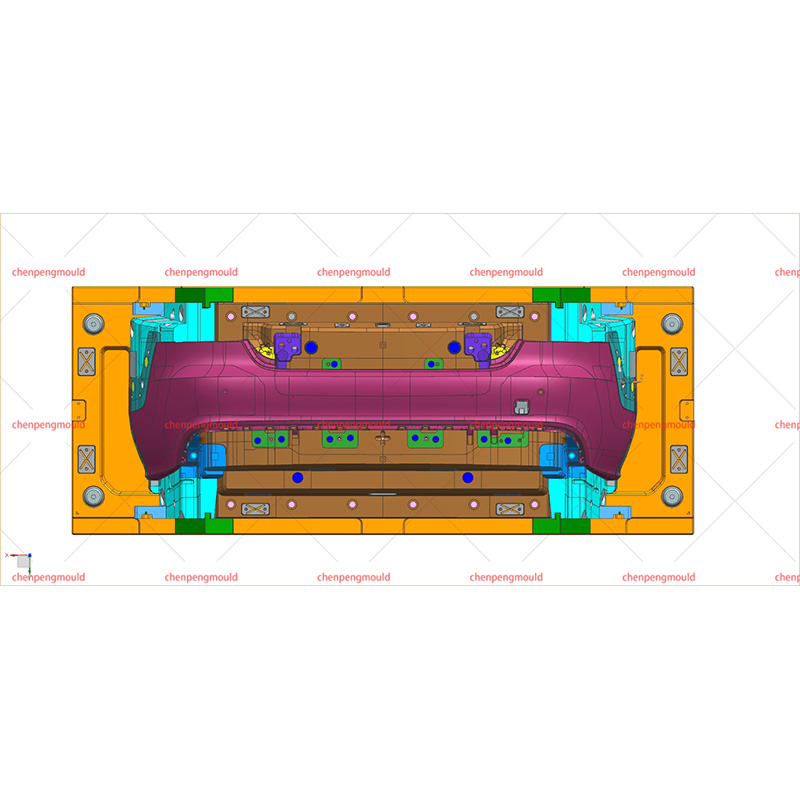

One of the primary materials used in China automotive bumper molds is steel. Known for its strength and durability, steel is an ideal choice for molds that must withstand the high pressures and temperatures of the injection molding process. China automotive bumper molds made from steel are designed to resist warping, cracking, or other forms of damage, ensuring a long lifespan even with repeated use. The durability of steel makes it a preferred material for China automotive bumper molds, allowing manufacturers to maintain consistent production without frequent mold replacements.

In addition to its durability, steel provides the precision required for China automotive bumper molds. The automotive bumper must fit on a vehicle, with precise dimensions and smooth surfaces. Steel's rigidity ensures that the mold retains its shape over time, allowing for accurate and consistent production of bumpers. This precision is crucial for automotive manufacturers who need to meet strict safety and design standards. China automotive bumper molds made from steel deliver the accuracy necessary for high-quality bumper production.

Aluminum is another material commonly used in China automotive bumper molds. While not as strong as steel, aluminum offers a lightweight alternative with thermal conductivity. This characteristic is beneficial in the injection molding process, where maintaining consistent temperatures is crucial for successful molding. Aluminum-based China automotive bumper molds can dissipate heat quickly, reducing the risk of defects and improving the efficiency of the manufacturing process. The lightweight nature of aluminum also makes it easier to handle and install, adding to its appeal for mold construction.

The choice between steel and aluminum for China automotive bumper molds often depends on the specific requirements of the manufacturing process. Steel is typically used for larger molds that require greater strength and durability, while aluminum is favored for smaller molds or those that need rapid heat dissipation. Both materials are highly reliable and can produce high-quality results when used appropriately. China automotive bumper molds constructed from steel or aluminum are designed to withstand the demands of automotive production, ensuring long-term performance and reliability.

Another important material used in China automotive bumper molds is copper. Although less common than steel and aluminum, copper is valued for its thermal conductivity. This property makes copper an ideal choice for inserts or components within the mold that require rapid cooling. Copper's ability to conduct heat efficiently helps maintain the integrity of the molding process, reducing the likelihood of defects and ensuring consistent results. China automotive bumper molds that incorporate copper can offer enhanced performance in specific applications where heat management is critical.

China automotive bumper molds may also include other specialized materials, such as polymers or composite materials, for specific purposes. These materials can be used to create intricate designs or add flexibility to the molding process. Polymers, for example, can be used in areas where a certain degree of elasticity is required, while composite materials may be used for complex shapes that require additional reinforcement. The use of these specialized materials adds versatility to China automotive bumper molds, allowing manufacturers to create a wide range of bumper designs with varying levels of complexity.

+86-18357617666

+86-18357617666