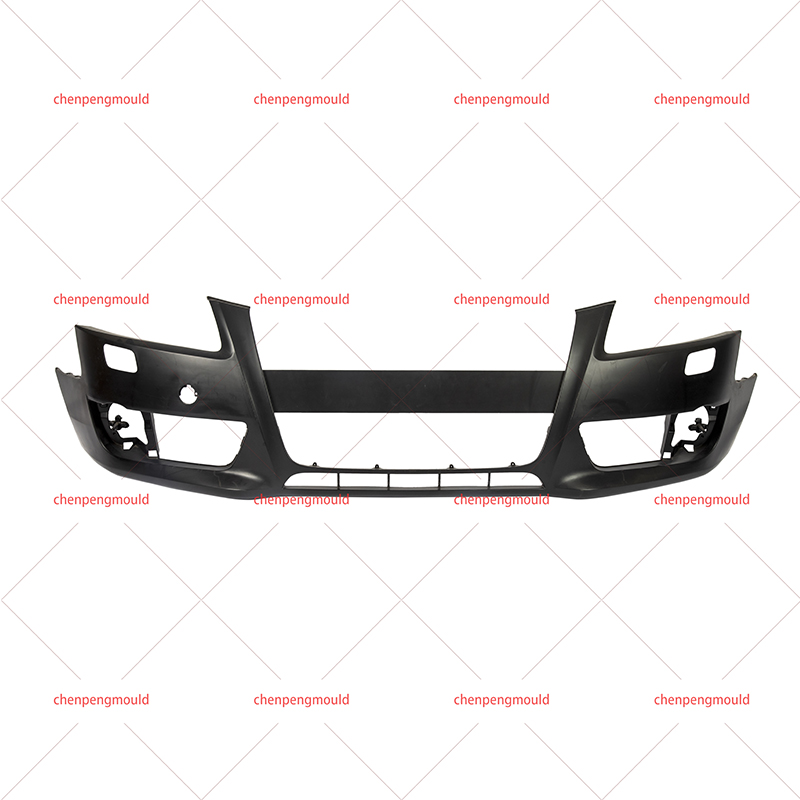

In the realm of automotive design and manufacturing, the choice of materials for front bumper covers has a significant impact on the overall performance, aesthetics, and durability of a vehicle. In recent years, the emergence of Fiberglass Front Bumper Cover Molding has introduced a new player in the automotive industry, challenging the traditional use of materials such as plastic and metal.

Traditionally, front bumper cover moldings have been crafted from materials such as plastic or metal. These materials have long been the standard due to their availability, ease of manufacturing, and ability to meet basic requirements for impact resistance and design flexibility. Plastic bumper covers are often used for their lightweight nature, while metal counterparts provide a sturdy and robust option. However, these materials come with their own set of limitations.

1. Weight: Metal bumpers, in particular, tend to add significant weight to the vehicle. This not only impacts fuel efficiency but also affects the overall handling and performance of the car.

2. Corrosion: Metal bumpers are susceptible to corrosion, especially in regions with harsh weather conditions. Exposure to moisture, salt, and other environmental factors can lead to rust, compromising both aesthetics and structural integrity.

3. Design Limitations: Traditional materials may pose design limitations, making it challenging to achieve intricate or aerodynamic shapes. This can hinder the creative freedom of automotive designers.

Enter Fiberglass Front Bumper Cover Molding, a revolutionary alternative that addresses many of the drawbacks associated with traditional materials. Fiberglass, composed of reinforced plastic fibers, presents a range of advantages that have garnered attention in the automotive industry.

Advantages of Fiberglass Front Bumper Cover Molding

1. Lightweight Design:

Fiberglass is inherently lightweight, offering a significant advantage over metal bumpers. The reduction in weight contributes to improved fuel efficiency, handling, and overall vehicle performance. Drivers benefit from a more agile and responsive driving experience, particularly in terms of acceleration and braking.

2. High Strength-to-Weight Ratio:

Despite its lightweight nature, fiberglass boasts a high strength-to-weight ratio. This means that Fiberglass Front Bumper Cover Molding can provide robust impact resistance and structural integrity without the excessive weight associated with metal alternatives. The result is a durable and reliable exterior component that stands up well to the challenges of everyday driving.

3. Corrosion Resistance:

One of the standout features of fiberglass is its resistance to corrosion. Unlike metal bumpers that may succumb to rust over time, Fiberglass Front Bumper Cover Molding maintains its integrity even in corrosive environments. This resistance ensures a longer lifespan for the bumper cover and contributes to the vehicle's overall longevity.

4. Design Flexibility:

Fiberglass offers unparalleled design flexibility, allowing for the creation of intricate and aerodynamic shapes. Automotive designers can push the boundaries of creativity, sculpting front bumper covers that not only enhance the vehicle's aesthetic appeal but also contribute to improved aerodynamics and performance.

5. Ease of Repair:

In the event of damage, Fiberglass Front Bumper Cover Molding is often easier to repair compared to traditional materials. Repair processes for fiberglass involve less complexity and cost, making it a more accessible option for both automotive technicians and car owners.

6. Customization Potential:

Fiberglass allows for a high degree of customization. Whether it's color, texture, or additional features, Fiberglass Front Bumper Cover Molding can be easily tailored to meet the specific preferences of car owners. This customization potential opens up new possibilities for personalization in the automotive industry.

Future Trends and Considerations

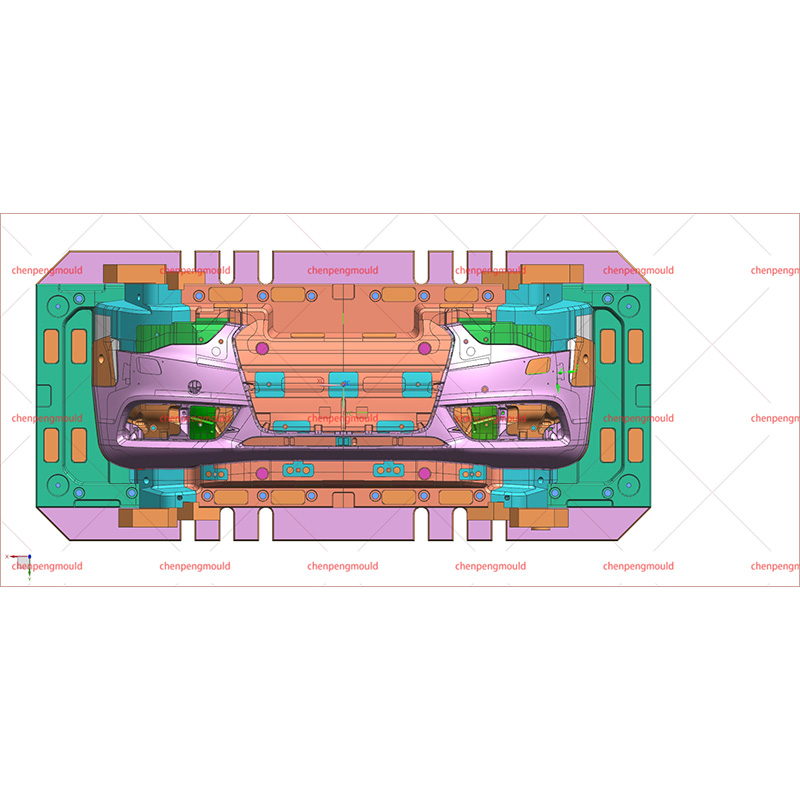

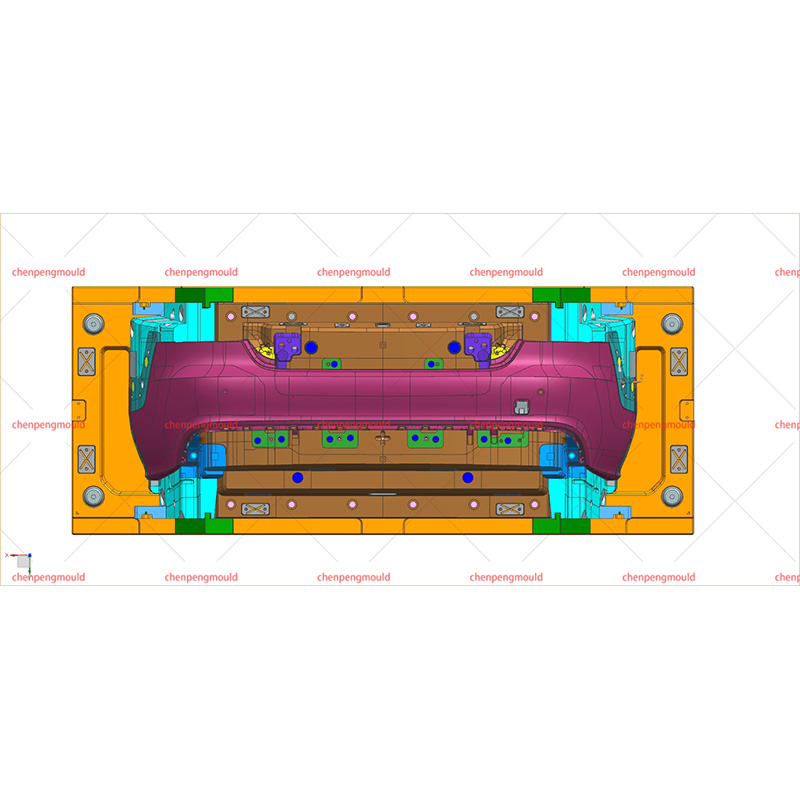

As the automotive industry continues to evolve, Fiberglass Front Bumper Cover Molding is likely to play a significant role in shaping future trends. Manufacturers are increasingly exploring sustainable options, and fiberglass, with its lightweight and recyclable nature, aligns with these environmental considerations. Additionally, advancements in manufacturing technologies, including the further refinement of Fiberglass Bumper Mold, may open up new possibilities for innovation and design in automotive exteriors.

+86-18357617666

+86-18357617666