China ODM Automotive Bumper Mold Sale Manufacturer Factory

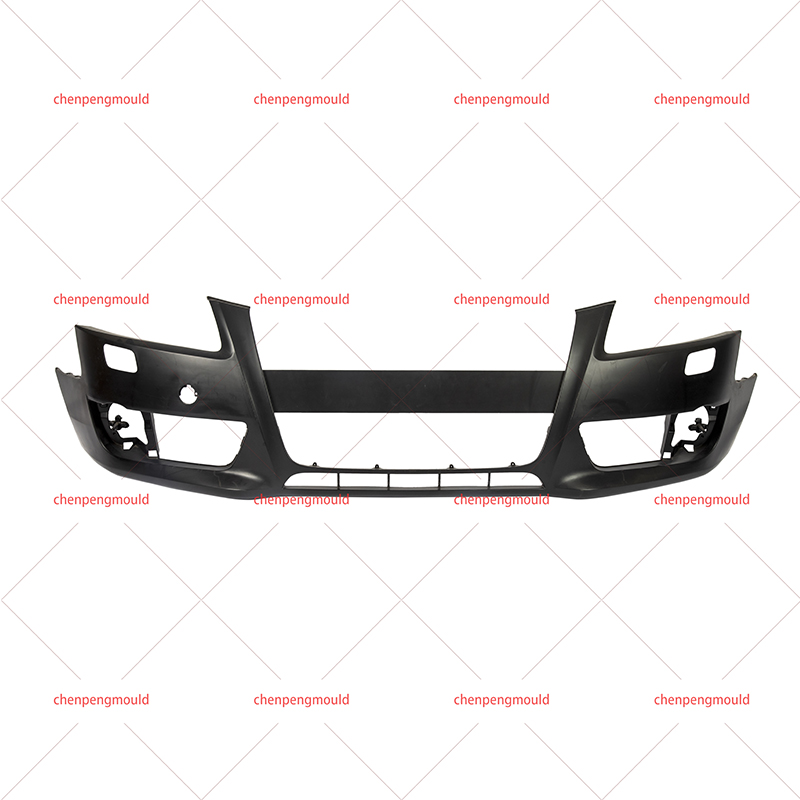

Automotive manufacturing relies heavily on precision and quality, especially when it comes to key components like bumpers. China automotive bumper molds have become synonymous with durability and detail-oriented craftsmanship, offering a solution for the high demands of the automotive industry. The importance of these molds extends beyond mere production—they are essential for ensuring safety, aerodynamics, and aesthetics.

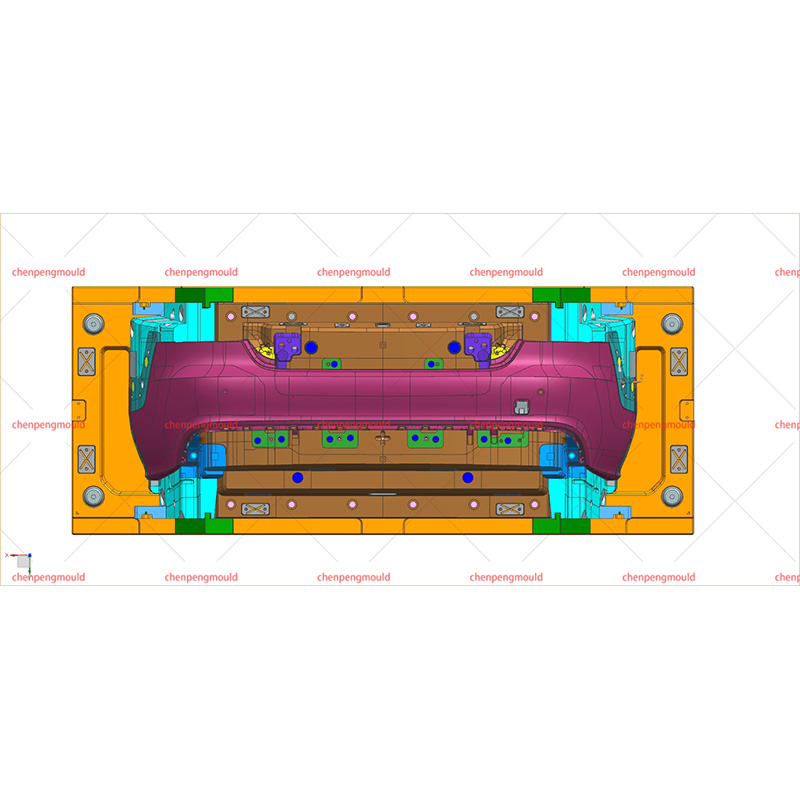

One of the defining characteristics of China automotive bumper molds is their durability. Molds used in the automotive industry must withstand repeated use without degrading, as they are integral to mass production processes. China automotive bumper molds are made from high-quality materials like steel and aluminum, ensuring they can endure the rigors of high-pressure injection molding. This durability translates into a longer lifespan for the molds, reducing the need for frequent replacements and downtime during production.

In addition to their durability, China automotive bumper molds are known for their precision. Automotive bumpers are not just aesthetic features—they play a critical role in vehicle safety and aerodynamics. Any deviation from the intended design can affect these critical functions. China automotive bumper molds are crafted with meticulous attention to detail, ensuring that every contour, curve, and attachment point is accurate to the original design specifications. This precision is key for manufacturers who need to maintain consistency and quality across large production runs.

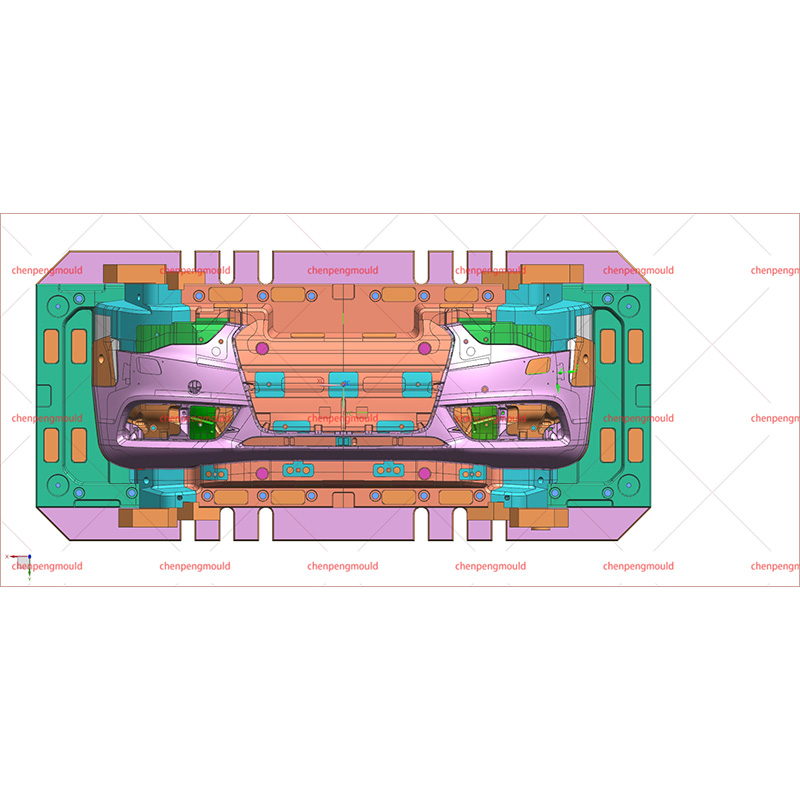

The advanced technology used in the creation of China automotive bumper molds contributes to their precision. CNC (Computer Numerical Control) machines are employed to shape the molds with incredible accuracy. This technology allows for complex designs and intricate details to be incorporated into the molds, ensuring that the final product meets or exceeds industry standards. The use of CNC machines also enhances the efficiency of the manufacturing process, allowing for faster turnaround times without compromising quality.

China automotive bumper molds are also renowned for their adaptability. The automotive industry is constantly evolving, with new designs and models being introduced regularly. Molds must be able to accommodate these changes, allowing manufacturers to keep pace with market demands. China automotive bumper molds are designed to be flexible, allowing for modifications and updates as needed. This adaptability is crucial for manufacturers who need to quickly respond to changing trends and customer preferences.

Another significant advantage of China automotive bumper molds is their cost-effectiveness. The manufacturing process in China benefits from economies of scale, reducing the overall cost of production. This cost advantage is passed on to automotive manufacturers, allowing them to obtain high-quality molds at competitive prices. The cost-effectiveness of China automotive bumper molds makes them an attractive option for manufacturers seeking to optimize their production budgets without sacrificing quality or precision.

The attention to detail in China automotive bumper molds is evident in their surface finish. Automotive bumpers require a smooth and polished surface to meet aesthetic standards and ensure proper painting and finishing. China automotive bumper molds are meticulously crafted to provide a flawless surface, reducing the need for additional post-production finishing. This focus on detail not only enhances the final product's appearance but also streamlines the production process, saving time and resources.

Collaboration and communication are key aspects of the manufacturing process for China automotive bumper molds. Manufacturers in China work closely with their clients to understand their specific requirements and design preferences. This collaborative approach ensures that the molds produced are tailored to the client's needs, allowing for a seamless integration into their production lines. The open lines of communication between Chinese manufacturers and their clients foster a strong partnership that contributes to the success of the final product.

+86-18357617666

+86-18357617666