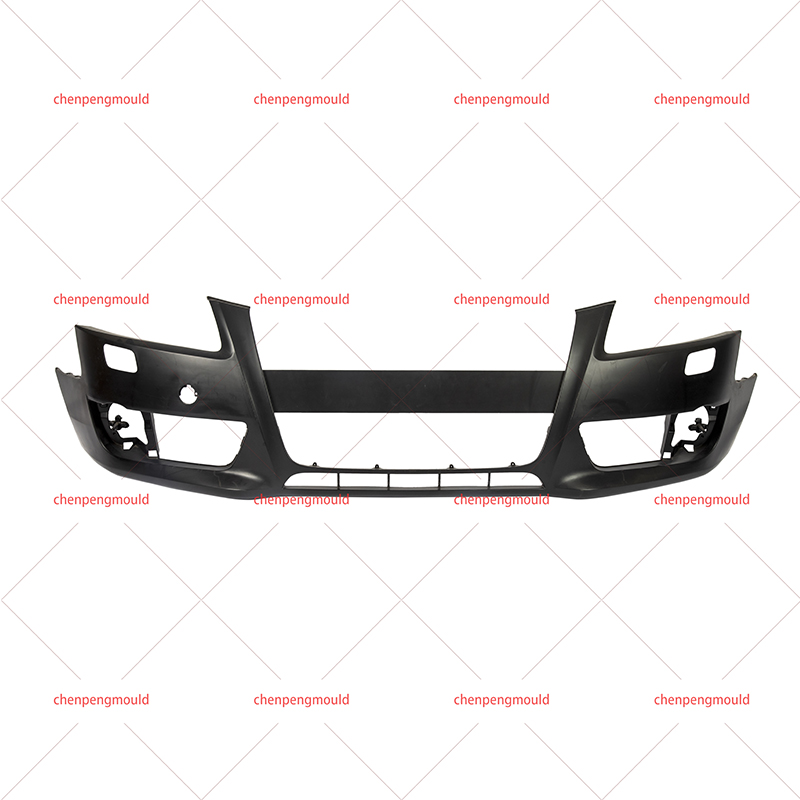

Cheap Car Bumper Injection Moulding in China Wholesaler

Car bumpers are critical components of vehicle safety and aesthetics, designed to absorb impact during collisions and enhance the overall appearance of automobiles. In the automotive industry, injection molding has emerged as the preferred method for producing car bumpers due to its efficiency, versatility, and cost-effectiveness. However, optimizing the car bumpers injection molding process requires careful consideration of various factors, including design, material selection, process parameters, and quality control measures.

Car bumper injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity under high pressure to produce bumper components. The process begins with the melting of thermoplastic resin pellets, which are then injected into a mold cavity using a reciprocating screw mechanism. Once the mold is filled, the plastic is allowed to cool and solidify, resulting in the formation of the desired bumper shape. Injection molding offers numerous advantages, including fast cycle times, high production volumes, and the ability to produce complex geometries with tight tolerances.

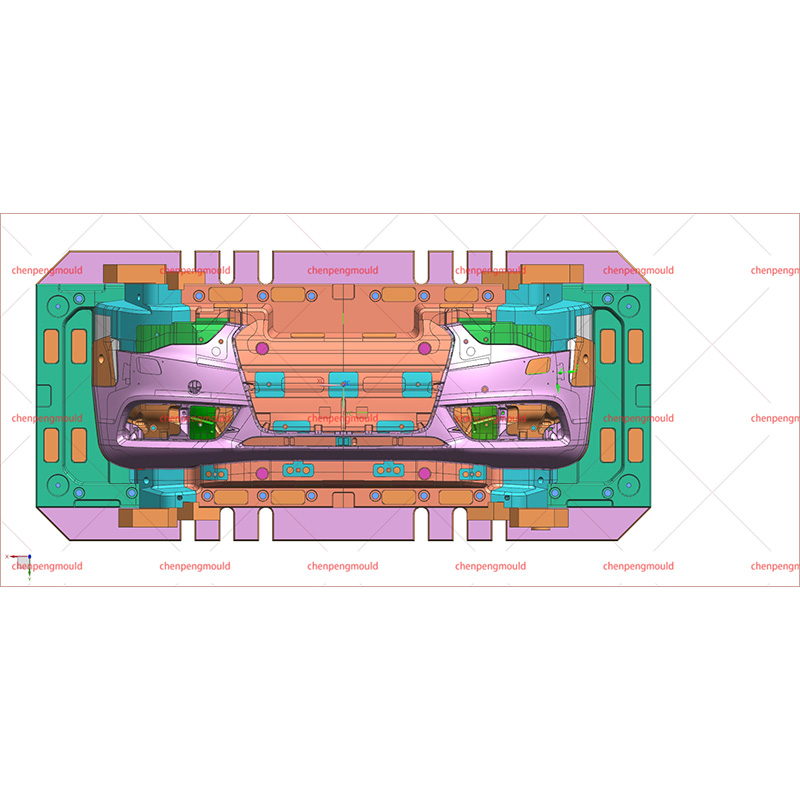

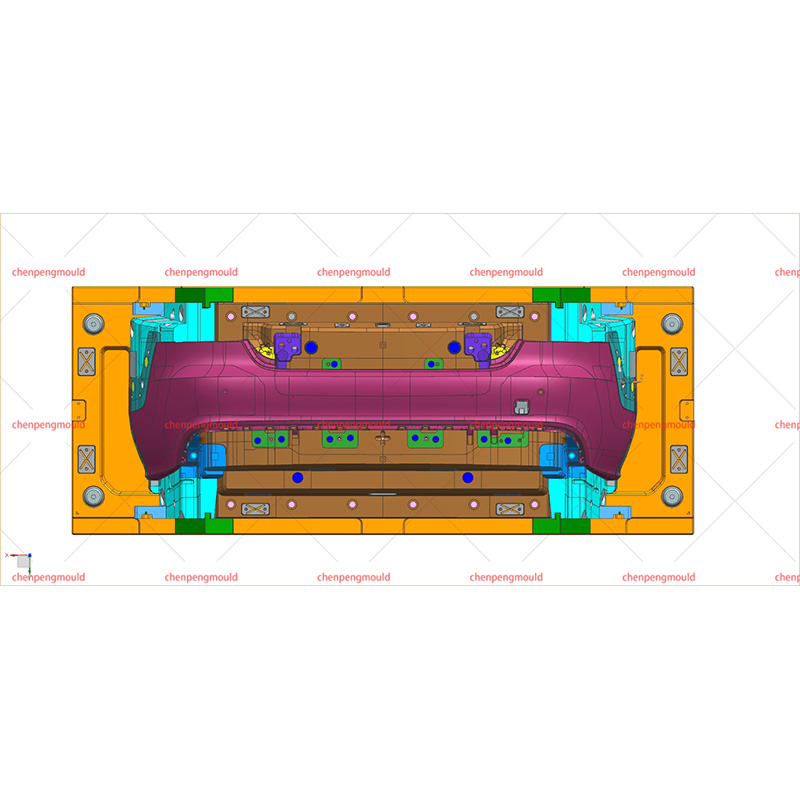

Design Considerations for Injection Molded Car Bumpers:

Optimizing the design of injection-molded car bumpers is crucial for achieving performance and aesthetics. Key design considerations include bumper geometry, thickness distribution, material selection, and structural reinforcements. By utilizing advanced CAD/CAM software and finite element analysis (FEA) tools, designers can optimize bumper designs to minimize stress concentrations, improve energy absorption, and enhance overall crashworthiness. Additionally, incorporating features such as ribs, bosses, and gussets can strengthen the bumper structure and reduce warpage during the molding process.

Material Selection and Compatibility:

The selection of appropriate materials plays a significant role in optimizing the car bumpers injection molding process. Thermoplastic polymers such as polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC) are commonly used due to their excellent mechanical properties, impact resistance, and moldability. However, selecting the right material involves considering factors such as temperature stability, chemical resistance, UV resistance, and recyclability. Conducting material compatibility tests and evaluating performance under real-world conditions can help identify the suitable material for specific bumper applications.

Process Parameters and Optimization Techniques:

Fine-tuning process parameters is essential for optimizing the car bumpers injection molding process and achieving consistent part quality. Key parameters to consider include injection speed, injection pressure, melt temperature, mold temperature, cooling time, and packing pressure. By conducting systematic process optimization experiments and utilizing statistical process control (SPC) techniques, manufacturers can identify the parameter settings that minimize cycle times, reduce scrap rates, and ensure dimensional accuracy. Additionally, implementing advanced molding technologies such as gas-assisted injection molding (GAIM) and co-injection molding can further enhance process efficiency and part quality.

Quality Control and Inspection Methods:

Maintaining strict quality control standards is essential throughout the car bumper injection molding process to ensure the integrity and performance of the final product. Quality control measures may include visual inspection, dimensional measurement, material testing, and non-destructive testing techniques such as ultrasonic inspection and X-ray imaging. By implementing automated inspection systems and in-line quality monitoring devices, manufacturers can detect defects in real time and take corrective action to prevent the production of non-conforming parts. Additionally, establishing robust process validation protocols and adhering to industry standards such as ISO 9001 and IATF 16949 can help ensure compliance and customer satisfaction.

Environmental Considerations and Sustainability:

In recent years, there has been a growing emphasis on environmental sustainability within the automotive industry, driving the adoption of eco-friendly manufacturing practices for car bumpers injection molding. By using recycled plastics, bio-based materials, and energy-efficient manufacturing processes, manufacturers can reduce carbon emissions, minimize waste generation, and promote resource conservation. Additionally, implementing closed-loop recycling systems and partnering with suppliers committed to sustainable practices can further enhance the environmental performance of injection molding operations.

+86-18357617666

+86-18357617666