Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professional wholesale Barbus Plastic Injection Mould supplier and quality Barbus Plastic Injection Mould factory in China. The company′s main business is the manufacturing and development of automotive exterior and interior mold and modified bumper mold, with strong forward product design and development capabilities. The company has strong experience in the design and development of automotive injection molds since 2000. The founder Mr. Yimin Jin of the company is well-known in the industry and has invented and created various structural designs of bumper molds, Structural design professional industry.

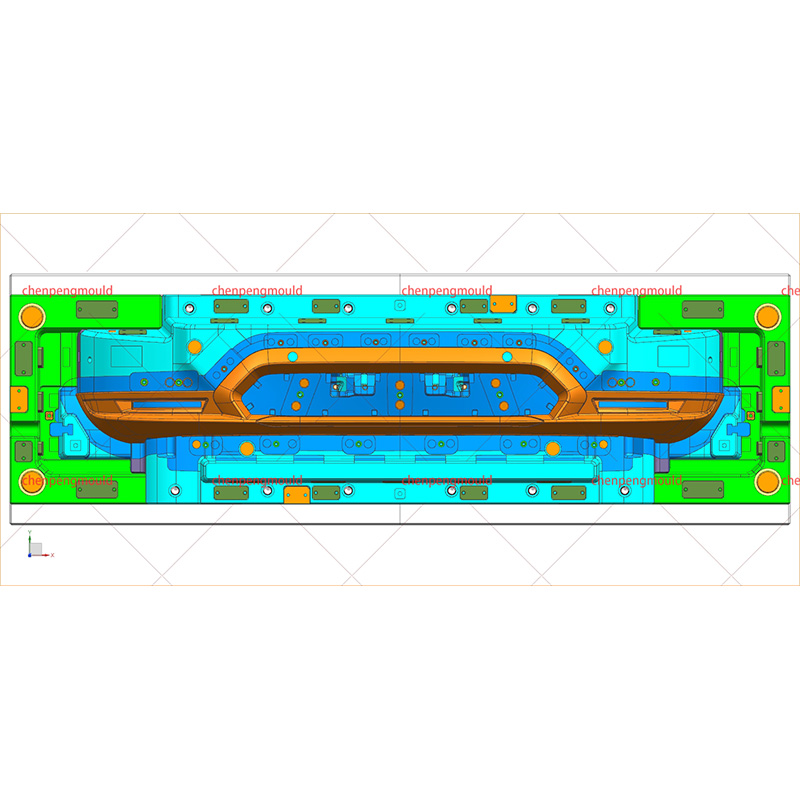

| Mould Name | Barbus Plastic Injection Mould |

| Material | PP+EPDM(Contraction: 1, 5%) |

| Steel For Cavity &. Core | P20 |

| Mould Base | C50 |

| NOs. of Cavity | 1*1 |

| Injection System | Yudo 5 direct injection gates |

| Ejection System | Ejector pins, angled-lift splits |

| Mould Standard | OEM/HASCO |

| Mould Weight | 13500KG |

| Injection Machine Size | 1850T |

| Mould Lifetime | 5years |

| Mould manufacturer Time | 50--90days |

-

Barbus Plastic Injection Mould

Why choose us?

Experience: We have had strong expertise in designing and developing automotive injection molds since 2000. Our company has developed 1000 bumper molds, including Volkswagen, Audi, Mercedes, BMW, Toyota, Ford, Skoda, etc. Moreover, we also developed higcarsbumper bumpers, like Rolls-Royce, Lamborghini I, Porsche Panam, er, an, etc.

Performance: Our bumper molds consistently deliver higher precision and quality in the molded parts compared to others.

Uniqueness:O ur bumper molds have unique features and innovations that set them apart. It includes advanced cooling systems, innovative design elements, and special coatings that improve durability and reduce cycle times.

Quality AssAssurancestressesss our commitment to quality assurance processes and standards that ensure the reliability and consistency of our bumper mold's output.

Longevity and Durability: Our bumper molds can maintain high performance over an extended period because of superior materials, reasonable structure, and excellent technology.

Customer Satisfaction: Our existing customers are delighted with our bumper molds and have been developing the design of the new design for us for a long time. An, now we are still working closely with our first who has worked with us for more than 20 years.

Cost-Effectiveness:O ur bumper molds can lower maintenance costs reduce scrap rates, and increase production yields, resulting in overall cost savings.

Continuous Improvement: we commit to constant improvement and innovation in mold design and manufacturing processes.